Flat Rubber Sealing Rings play a crucial role in ensuring the integrity and efficiency of various mechanical applications. As more industries adopt advanced technologies and increasingly complex systems, the selection of these sealing solutions becomes paramount for achieving optimal performance. Understanding the various factors that influence the effectiveness of Flat Rubber Sealing Rings is essential for engineers and maintenance professionals tasked with guaranteeing the reliability of equipment across different environments.

In this 2025 guide, we will explore the key considerations necessary for choosing the right Flat Rubber Sealing Rings. From material selection to design specifications, each aspect significantly impacts the sealing rings' functionality and durability. Properly chosen, these sealing rings can prevent leaks, protect against contamination, and contribute to the overall efficiency of machinery. With the imminent advancements in technology, ensuring that your sealing solutions meet the demands of modern applications is more important than ever. Join us as we navigate through the essential criteria to help you make informed decisions and enhance operational performance.

Flat rubber sealing rings play a crucial role in a wide array of industrial applications, serving as a barrier to prevent the leakage of fluids and gases. Understanding the basics of these sealing solutions is essential for selecting the right materials and designs that ensure optimal performance. According to a market report from Global Industry Analysts, the global rubber sealing market is projected to reach approximately $76 billion by 2027, highlighting the increasing reliance on these components for effective sealing purposes.

The primary function of flat rubber sealing rings is to provide a tight fit that minimizes the possibility of leakage. Their performance is heavily influenced by factors such as temperature resistance, chemical compatibility, and compression set. For instance, specialized rubber compounds, like EPDM and nitrile, are often employed for their excellent resistance to heat and aggressive chemicals. A study published in the Journal of Materials Science revealed that proper material selection can enhance sealing effectiveness by as much as 30%, significantly reducing the risk of fluid loss in critical machinery.

Moreover, understanding the sizing and installation of flat rubber sealing rings is vital to ensuring long-term reliability. The sealing effectiveness can be compromised if the rings are improperly sized or if foreign contaminants impede their function. According to the Sealing Association's latest guidelines, maintaining a clean installation environment can increase the longevity and performance of these sealing components by up to 40%. By prioritizing material properties and installation best practices, engineers can enhance the durability and efficiency of applications utilizing flat rubber sealing rings.

When selecting flat rubber sealing rings, several key factors significantly influence their performance. One crucial aspect is the material composition of the sealing ring. Different rubber compounds exhibit varied resistance to temperature fluctuations, chemicals, and wear. For instance, nitrile rubber offers excellent oil resistance, while silicone rubber excels in high-temperature applications. It is essential to evaluate the operational environment to determine the most suitable material, ensuring the sealing rings withstand the stresses they will encounter.

Another important factor is the design and dimensions of the sealing rings. The thickness, diameter, and cross-sectional shape directly impact the sealing efficiency and ability to accommodate variations in pressure and temperature. Proper sealing ring geometry enables better compression and creates a tighter seal, which prevents leaks effectively. Additionally, considering the installation conditions, such as surface roughness and alignment, can further enhance the sealing performance and longevity of the rings. By paying close attention to these elements, users can select the most appropriate flat rubber sealing rings for their specific applications.

When selecting flat rubber sealing rings, the choice of material is critical for ensuring optimal performance in various applications. The composition of rubber plays a significant role in the sealing effectiveness, durability, and resilience of the rings. According to a report from Smithers Pira, the global demand for rubber sealing products is projected to reach approximately 740,000 tons by 2025, driven primarily by advancements in automation and rising industrial activities. This surge underscores the importance of selecting appropriate rubber materials that can withstand diverse operating conditions.

Natural rubber, while known for its excellent elasticity, may not be suitable for high temperatures or exposure to certain chemicals. In contrast, synthetic rubbers such as nitrile (NBR) and fluoroelastomers (FKM) provide enhanced resistance to oils and solvents, making them favorable choices for automotive and industrial applications. A study published by Technavio highlights that the automotive industry's demand for high-performance sealing materials is projected to witness a growth of 4.2% annually through 2025. Consequently, the selection of the right rubber material should consider factors such as temperature range, chemical exposure, and mechanical stresses to ensure longevity and effectiveness of the sealing rings.

| Material Type | Temperature Resistance (°C) | Chemical Compatibility | Compression Set (% - 22hrs @ 100°C) | Cost ($ per kg) |

|---|---|---|---|---|

| Nitrile (NBR) | -40 to 120 | Oil, Fuel | 25 | 4.50 |

| Fluoroelastomer (FKM) | -15 to 200 | Aromatics, Oxygen | 20 | 10.00 |

| Silicone (VMQ) | -50 to 200 | Water, Ozone | 30 | 6.00 |

| Ethylene Propylene Diene Monomer (EPDM) | -40 to 150 | Ozone, Weather | 15 | 3.50 |

| Neoprene (CR) | -40 to 120 | Moderate Oil | 25 | 5.00 |

Installation of flat rubber sealing rings is critical for ensuring their optimal performance and longevity in various applications. According to a recent industry report, improper installation is responsible for approximately 40% of failures in sealing solutions. Achieving the best results begins with thoroughly cleaning the surface where the sealing ring will be applied. Contaminants such as dust, oil, and moisture can compromise the effectiveness of the seal, leading to leaks and increased wear. Utilizing appropriate tools and techniques, such as applying even pressure while positioning the rings, can significantly enhance their performance.

Moreover, ensuring the right fit and proper torque during assembly is essential. A study from the Sealing Technology Association indicated that approximately 30% of sealing failures arise from incorrect sizing. This underlines the importance of pre-measuring grooves and selecting sealing rings that adhere to specified tolerances. When installed at the correct torque specifications, the sealing rings can maintain a tight fit, reducing the likelihood of premature wear or failure. It is also beneficial to consult industry guidelines regarding installation procedures to adapt best practices in line with specific operational conditions and material compatibilities.

Flat rubber sealing rings are essential components widely utilized across various industries due to their versatility and effectiveness in creating airtight and watertight seals. In the automotive industry, for example, these rings are commonly used in engines, fuel systems, and hydraulic applications. Their ability to withstand high temperatures and pressures makes them ideal for preventing leaks and ensuring optimal performance of engine parts, contributing to vehicle longevity and efficiency.

In the HVAC (Heating, Ventilation, and Air Conditioning) industry, flat rubber sealing rings play a critical role in preventing air and fluid leaks in ductwork and piping systems. These seals are vital in maintaining energy efficiency and performance, as they help ensure that systems operate smoothly without losing conditioned air. Similarly, in the food and beverage sector, rubber seals are crucial for maintaining hygiene and safety standards, sealing containers and machinery to prevent contamination and preserve product integrity during processing and storage. Such diverse applications highlight the importance of selecting the right flat rubber sealing rings tailored to specific industrial needs.

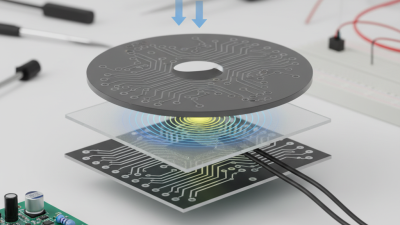

This chart illustrates the common applications of flat rubber sealing rings across various industries, displaying the performance impact of using the correct sealing materials.