In 2026, RTV molding techniques are evolving rapidly, shaping various industries. The global RTV molding market is projected to reach $3 billion by 2025, reflecting substantial growth. Companies are shifting toward precision applications, highlighting the importance of reliable methods and materials.

Innovative techniques are redefining production processes. For instance, advancements like silicone rubber options enhance flexibility and durability. Yet, many manufacturers face challenges like maintaining quality while scaling production. This tension creates room for reflection on best practices.

As the industry matures, embracing new applications is vital. RTV molding plays a crucial role in sectors like automotive and healthcare. Understanding these trends helps companies stay competitive in a crowded market. Balancing innovation with practicality remains a key challenge.

RTV molding techniques are experiencing a renaissance. New methods and innovations are transforming industries. These advancements increase efficiency and improve product quality. Emerging techniques focus on precision, speed, and versatility.

One exciting development is the use of 3D printing technology. This blends well with RTV molding. It allows for creating intricate designs quickly. The results are often more precise than traditional methods. However, mastering this combination can be challenging. Experimentation is key; results vary greatly.

Tips: Start with small projects. Test materials and settings gradually. This helps avoid costly mistakes. Use silicone molds to explore different shapes and textures. Each attempt provides valuable insights and improves skills. Embrace the learning curve; it’s essential for growth.

Another point of interest is the eco-friendly materials now available. Many companies are shifting focus towards sustainability. These materials can offer similar performance to traditional ones. But they may come at a higher cost. Balancing sustainability with budget constraints demands careful planning. Streamlining processes can help mitigate expenses.

Endless opportunities await those willing to innovate in RTV molding. Keep up with trends and embrace new technologies. Exploring these advancements can lead to remarkable breakthroughs in your projects.

RTV molding is gaining traction across various industries due to its adaptability and efficiency. In automotive manufacturing, it plays a crucial role in producing intricate parts that require precision. Components like gaskets and seals benefit from RTV's flexibility. This material can handle high temperatures and harsh conditions, making it ideal for automotive applications.

In the aerospace sector, RTV molding is vital for creating lightweight yet durable components. Designers often seek better methods for weight reduction without sacrificing safety. Applications include engine components and interior parts that require both strength and aesthetics. However, the challenge remains in ensuring uniformity and performance across different batches.

Consumer electronics also leverage RTV molding for enclosures and protective casings. The need for innovation is constant, with designers striving to create sleek, functional devices. Yet, the concern of environmental impact is significant. Sustainable molding techniques are a point of reflection. Addressing waste generation in this rapidly evolving field is key. As industries adopt RTV molding, the focus must shift to creating efficient and eco-friendly solutions.

RTV molding, or room temperature vulcanization molding, stands out when compared to traditional molding methods. It uses liquid silicone that cures at room temperature, allowing for quicker production times. This technique is versatile and can create intricate designs with fine details. It’s an excellent choice for prototypes and small batches. However, users may find the initial setup costs higher than those of conventional methods.

Traditional molding often relies on rigid tooling. This can lead to longer lead times due to the need for precise molds. The materials used may limit the complexity of designs, making RTV molding more appealing for creative applications. Yet, RTV molding presents its own challenges. The curing process may sometimes yield uneven results. Furthermore, maintaining quality control can be harder, especially with varying environmental conditions.

In specific applications, RTV can provide a higher level of customization. It allows designers to experiment with different shapes and textures. Production efficiency is notable, but it requires careful attention to detail. Without this, results can be subpar. RTV molding is revolutionary, but like any technique, it is not flawless and warrants continuous evaluation.

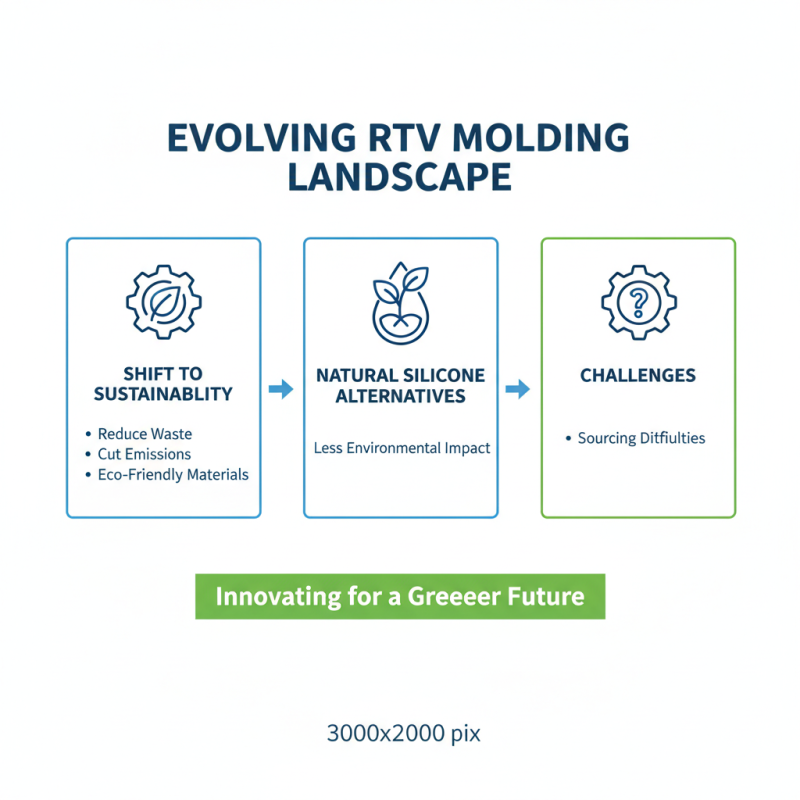

The landscape of RTV molding is evolving rapidly. Sustainable practices are gaining traction in this industry. Many companies are seeking eco-friendly materials. They want to reduce waste and cut down emissions. Natural silicone alternatives are being explored. These materials can lessen the environmental impact. However, sourcing these materials can be challenging.

Energy-efficient processes are also important. Traditional molding methods consume a lot of power. New techniques aim to minimize energy use. Some facilities are investing in renewable energy sources. Still, transitioning to greener practices can be costly. It often requires a complete overhaul of existing systems.

There’s a learning curve involved. Not every company can adapt easily. Mistakes can occur while testing new techniques. Some processes may not yield the desired results. It’s crucial for firms to continuously evaluate and improve. Sustainable RTV molding has great potential but also faces hurdles. Each step toward a greener future demands careful consideration.

RTV molding technology has evolved significantly over the years. It offers unique benefits in various applications. However, challenges still persist. One area of concern is the consistency of the molding process. Variations in temperature and humidity can affect results. Achieving uniformity is not always straightforward. This inconsistency can lead to defects, which are costly to address.

Future directions in RTV molding may focus on advanced materials. These materials could enhance performance and reduce failures. Innovations like smart additives might improve durability. On the other hand, the sustainability of these new materials is a critical issue. Manufacturers must consider environmental impacts. Balancing innovation with eco-friendliness is a significant challenge.

Another area for growth is automation in the RTV molding process. Robots can enhance production speed and reduce labor costs. Yet, there are limitations to automation. Not all tasks can be easily automated. Skilled workers are still essential for quality control. The integration of new technology requires ongoing training and adaptability. This can be a hurdle for many companies.