Rubber bumpers play a crucial role in protecting various surfaces from damage. John Smith, a leading expert in material science, states, "The right rubber bumpers can prevent costly repairs and prolong the lifespan of equipment." Choosing the best rubber bumpers requires understanding their applications and materials.

Many industries rely on rubber bumpers for safety and durability. These components absorb shock and minimize friction. They can be found in furniture, machinery, and vehicles, providing essential protection. However, not all rubber bumpers are created equal.

Some products may fail under pressure or wear out too quickly. It’s essential to choose bumpers that meet specific needs. Customers often overlook the importance of quality in this area. Selecting the right rubber bumper is key to avoiding future complications. Investing in durable options pays off in the long run.

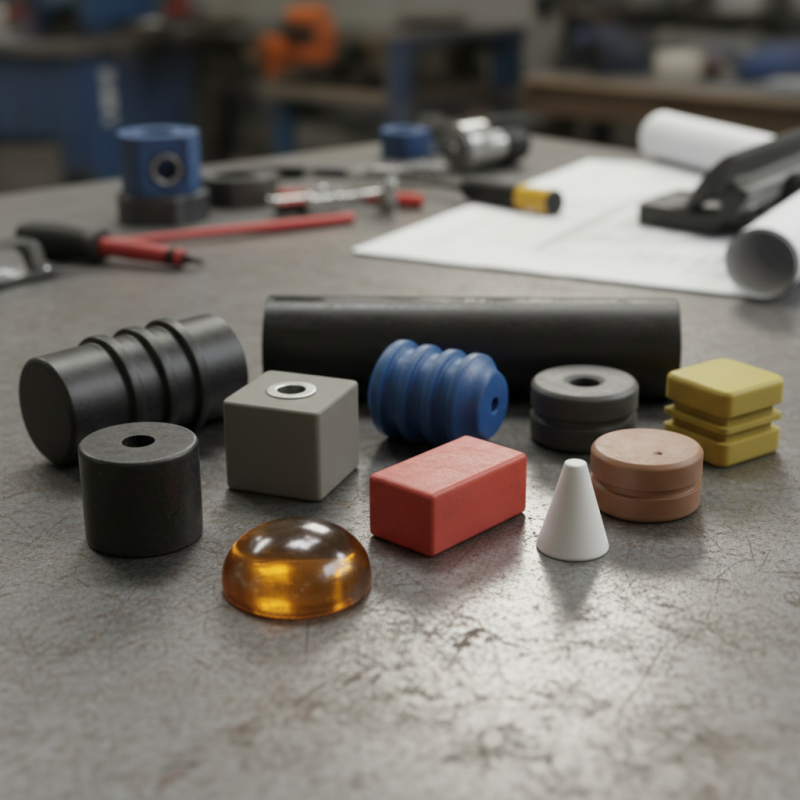

Rubber bumpers play a crucial role in various industries. They provide essential protection and durability for items ranging from appliances to industrial machinery. Understanding the types and materials of rubber bumpers can help in making informed choices.

There are primarily three types of rubber bumpers: solid rubber, cushioned rubber, and foam rubber. Solid rubber bumpers offer maximum durability and resistance to wear, making them ideal for heavy-duty applications. A report by the International Rubber Study Group highlights that solid rubber accounts for over 40% of the rubber market due to its longevity and performance. Cushioned rubber bumpers, on the other hand, provide excellent shock absorption. This makes them suitable for lightweight equipment and delicate surfaces. Foam rubber, while less durable, has its place in applications requiring lightweight cushioning.

Material selection affects the overall effectiveness of rubber bumpers. Natural rubber is known for its elasticity and strength, while synthetic alternatives like neoprene and EPDM provide enhanced resistance to heat and chemicals. According to recent industry surveys, approximately 35% of manufacturers opt for synthetic rubber in outdoor applications. These materials often come with trade-offs in cost and performance. Choosing the right bumper involves balancing these factors, while also considering the specific environment in which it's used.

When looking for high-quality rubber bumpers, key features matter. Material type is critical. Natural rubber provides excellent resilience and flexibility. Synthetic blends often offer better weather resistance and durability. Choose bumpers that withstand impacts while minimizing wear and tear.

Look for hardness ratings. Softer bumpers absorb shock better. However, they may wear out quickly. Harder bumpers last longer but may not cushion as effectively. Finding a balance is essential. Consider your specific needs for protection and longevity.

For enhanced performance, check adhesive strength. Strong adhesion ensures the bumper stays in place. Weak bonds lead to detachment and potential damage. Always inspect your bumpers for signs of wear. Replace them when you notice cracking or hardening.

Tips:

1. Test bumpers in different conditions.

2. Measure the area for exact fit.

3. Regular maintenance can prolong bumper life.

Choosing the right rubber bumpers is critical for protecting surfaces. High-quality bumpers not only absorb shock but also enhance durability. Studies show that rubber bumpers can reduce impact force by up to 70%. This significantly lowers the risk of damage to both the bumper and the surface it protects.

There are various types of rubber bumpers available. Some have softer compositions, which provide a gentler touch. Others are firmer, offering maximum resistance to wear and tear. Selecting the right type depends on the specific application. It’s important to think about the weight and movement of items they will safeguard. Some applications require greater resilience than others, leading to the potential for misalignment in expectations and performance.

Despite their advantages, not all rubber bumpers are created equal. Some products may degrade over time when exposed to certain environments. For instance, heat and sunlight can lead to deterioration. Regular assessments are necessary to ensure that bumpers are still effective. Monitoring their condition can prevent accidents and unnecessary repairs, contributing to long-term safety and cost savings.

When installing rubber bumpers, preparation is key. Start by choosing the right surface. Ensure it’s clean and level. Dust, dirt, or moisture can hinder adhesion. If the surface is uneven, it may lead to potential instability over time. A smooth installation prevents unnecessary wear and tear on the bumpers.

Proper alignment is crucial during installation. Measure carefully before applying adhesive. Misalignment can cause bumpers to wear unevenly, reducing their lifespan. Consider using a template for precision. Once applied, press firmly and hold for a few seconds. This will enhance adhesion, ensuring that they stay in place.

Keep in mind that the environment can impact performance. Extreme temperatures might affect the material. Regularly check the condition of your bumpers. Look for signs of wear or damage. Early detection can prevent larger issues. Remember, even the best products require maintenance for optimal performance.

Rubber bumpers are essential for protecting surfaces and preventing damage. To enhance their lifespan, certain maintenance practices are crucial. Regular inspection is vital. According to industry reports, neglected bumpers can degrade significantly within a year. Checking for cracks or wear allows early detection of potential failures.

Tip: Clean bumpers with mild soap and water. Chemicals can deteriorate the rubber. Use a soft cloth, as abrasives can cause scratches. Keeping bumpers free of debris prevents unexpected damage during use.

Storage conditions also impact durability. Excessive heat or moisture can warp rubber bumpers. Research shows that maintaining an optimal temperature reduces deterioration by up to 30%. Store them in a cool, dry environment.

Tip: Rotate your bumper stock. This practice ensures even wear and prevents certain bumpers from aging faster than others. Regular maintenance is not only about immediate appearance. It's about extending the functional life of these protective tools.

| Bumper Type | Material | Weight Capacity | Temperature Resistance | Durability Rating |

|---|---|---|---|---|

| Flat Rubber Bumper | Natural Rubber | 300 lbs | -40°F to 200°F | Excellent |

| Round Rubber Bumper | EPDM Rubber | 250 lbs | -50°F to 220°F | Very Good |

| Corner Rubber Bumper | Silicone Rubber | 200 lbs | -60°F to 300°F | Excellent |

| Heavy-Duty Bumper | Nitrile Rubber | 400 lbs | -40°F to 250°F | Outstanding |

| Adhesive Backed Bumper | PVC Rubber | 150 lbs | 0°F to 180°F | Good |

| Shock Absorbing Bumper | SBR Rubber | 350 lbs | -30°F to 220°F | Very Good |

| Non-Marking Bumper | Polyurethane | 250 lbs | -20°F to 180°F | Good |

| Weather-Resistant Bumper | Neoprene Rubber | 300 lbs | -40°F to 200°F | Outstanding |

| Custom Shaped Bumper | Vulcanized Rubber | 350 lbs | -30°F to 250°F | Excellent |