In the world of sealing solutions, the **Rubber Seal O Ring** stands out for its versatility and reliability. According to recent industry reports, O-Rings account for a significant portion of sealing components in various applications. Their unique design allows them to maintain a secure seal in a variety of environments, from automotive to aerospace.

However, not all O-Rings are created equal. Factors such as material composition and temperature tolerance vary widely among different products. A study indicated that nearly 30% of sealing failures arise from using inappropriate O-Ring materials. This emphasizes the need for careful selection in applications requiring optimal performance.

The market for rubber seals is projected to grow steadily, with specific demand for high-quality Rubber Seal O Rings. Though available options are plentiful, choosing the wrong type could lead to costly leaks or system failures. It is crucial to understand specific needs for sealing efficiency and durability. Recognizing the potential pitfalls is essential when navigating this complex landscape.

When considering rubber seal O rings, it's crucial to understand the types and materials available. O rings are circular seals designed to fit into a groove, creating a tight seal when compressed. Common materials include silicone, nitrile, and fluorocarbon. Each material serves different purposes and environments. Silicone O rings are flexible and resist high temperatures. Nitrile is often used in fuel applications due to its resistance to oils. Fluorocarbon O rings are great for chemical resistance.

Choosing the right material can be challenging. Not all O rings provide the same durability or flexibility. Some might wear out quickly under harsh conditions. Frequent replacements can be costly and time-consuming. Keep this in mind when selecting your O rings. It’s essential to consider the specific application and environment before making a choice.

**Tips:** Always check the compatibility of the material. Test different types if possible. Look for feedback from users in similar applications. A little research can save you from costly mistakes. Make sure to measure the groove accurately for an optimal fit.

When selecting rubber seal O rings, several key features are essential for optimal performance. Material type is crucial. Common materials include Buna-N, silicone, and EPDM. Each material has unique properties. Buna-N is excellent for oil resistance, while silicone can withstand extreme temperatures.

Sizing is equally important. The inner diameter and cross-section must match the application. Misjudging size can lead to leaks and failures. According to a ReportLinker study, improper sealing accounts for 30% of industrial failure rates. Understanding these metrics can help prevent costly mistakes.

Tip: Always consult technical datasheets from manufacturers. They provide valuable information on the recommended applications and limitations of each O ring type.

Another factor to consider is the durometer hardness. This affects the seal's compressibility. A higher hardness may lead to better wear resistance but could also result in a less effective seal. A balance is necessary.

Tip: Conduct field tests when possible. Real-world conditions may differ from theoretical applications. These tests can uncover flaws in your initial selection.

In conclusion, consider material, size, and hardness when choosing rubber O rings. Make choices based on thorough research and practical testing to avoid common pitfalls in sealing applications.

| O Ring Size | Material | Durometer (Shore A) | Temperature Range (°F) | Application |

|---|---|---|---|---|

| 2.5 x 1.5 mm | Nitrile | 70 | -40 to 250 | Hydraulic Applications |

| 3 x 2 mm | Viton | 75 | -20 to 400 | Chemical Applications |

| 5 x 3 mm | Silicone | 60 | -80 to 450 | Food Grade Applications |

| 4 x 2.5 mm | EPDM | 70 | -40 to 300 | Water Applications |

| 6 x 3.5 mm | Neoprene | 65 | -40 to 200 | General Purpose |

When considering sealing solutions, the choice of rubber seal O rings is crucial. These components play a vital role in preventing leaks across various applications. According to industry reports, the global rubber O ring market is anticipated to reach $1.5 billion by 2026, growing at a CAGR of 5.6%. This growth highlights the increasing demand for reliable sealing solutions across sectors such as automotive, aerospace, and construction.

Selecting the right O ring involves understanding the material properties. Nitrile, silicone, and fluorocarbon are popular choices. Each material offers unique benefits and limitations. For instance, while nitrile provides excellent resistance to oil, it may not perform well at high temperatures. Silicon rings, on the other hand, excel in extreme temperatures but may not withstand certain chemicals. It's essential to evaluate these factors carefully. An oversight at this stage can lead to premature failure, ultimately complicating operations.

In the quest for optimal sealing performance, the choice also extends to sizes and profiles. Standard round O rings may not be suitable for all applications. Custom shapes are often needed to fit specific designs. Measurement errors can lead to unacceptable gaps. Research indicates that up to 30% of sealing failures stem from incorrect sizing. Thus, achieving the perfect fit demands meticulous attention. Failure to do so can result in significant product leakage, operational downtime, and costly repairs.

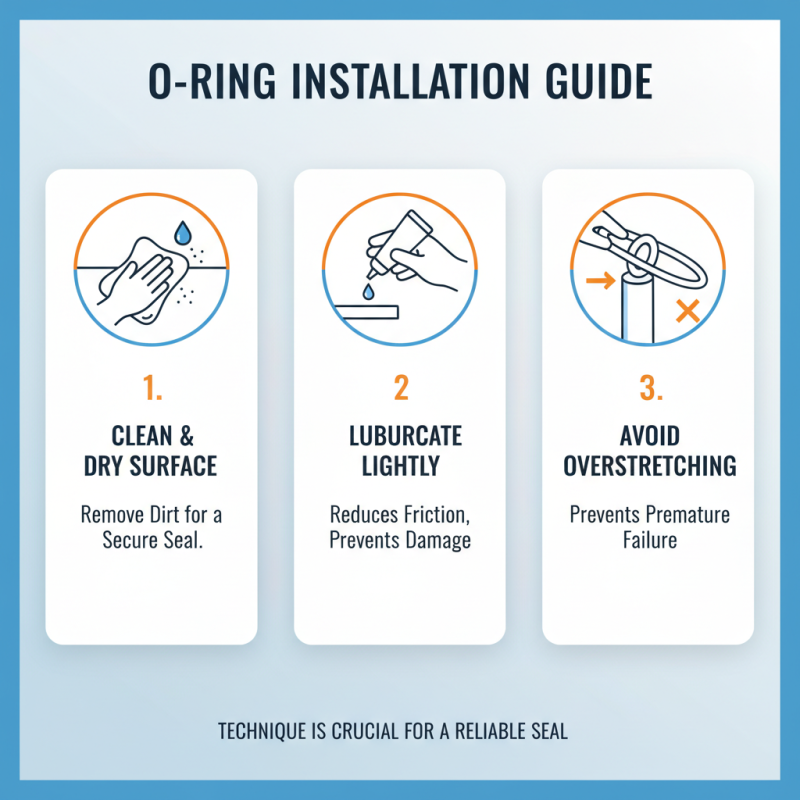

When installing rubber O rings, proper technique is crucial. Begin by ensuring the surface is clean and dry. Any dirt can compromise the seal. Use a small amount of lubricant for easier installation. It helps to reduce friction and avoid damage to the ring. Be careful not to over-stretch the O ring, as that can lead to premature failure.

Regular maintenance is equally important. Check for signs of wear and tear. Cracks or deformation are indicators that replacement is needed. Pay attention to the environment as well. Extreme temperatures or exposure to chemicals can degrade the rubber. Keeping a log of inspections may help in planning timely replacements.

Understanding these factors can enhance the durability of your O rings. Replacement might not always be immediate, but postponing it too long can cause leaks. Regular checks and proper installations can improve sealing performance. Small actions can lead to better outcomes.

Rubber seal O rings are essential in various industries. They create effective seals, preventing leaks and contamination. These rings are used in hydraulic systems, automotive applications, and home appliances. Their versatility and reliability make them a popular choice for manufacturers.

In hydraulic systems, rubber O rings are crucial for maintaining pressure. The right size and material ensure a tight fit. They help avoid fluid leaks that could lead to failures.

In automotive applications, O rings are used in engines and fuel systems. They withstand high temperatures and pressures, improving safety and performance.

Home appliances also benefit from rubber O rings. They are found in dishwashers and washing machines. A faulty O ring can cause water leaks, leading to damage.

This simple component often requires careful inspection and replacement. It’s a reminder that even small parts are vital.