In the world of smart technology, Ito Conductive technology stands out as a game-changer. Experts like Dr. Emily Hu, a renowned authority in the field, emphasize its potential, stating, “Ito Conductive changes how we interact with devices.” This innovation allows for seamless touch interfaces and transparent displays that shape our daily experiences.

Understanding how to optimize the use of Ito Conductive technology is essential for developers and manufacturers. Each application may require a unique approach. For instance, the integration of this technology in wearable devices presents challenges in durability and flexibility. Companies must fine-tune designs to enhance user interaction while ensuring reliability.

However, not every application has achieved perfection. Some implementations show limitations regarding responsiveness. It is crucial for professionals to continuously refine their strategies. This iterative process can lead to breakthroughs that fully harness the power of Ito Conductive technology. The journey involves trial, error, and a commitment to innovation.

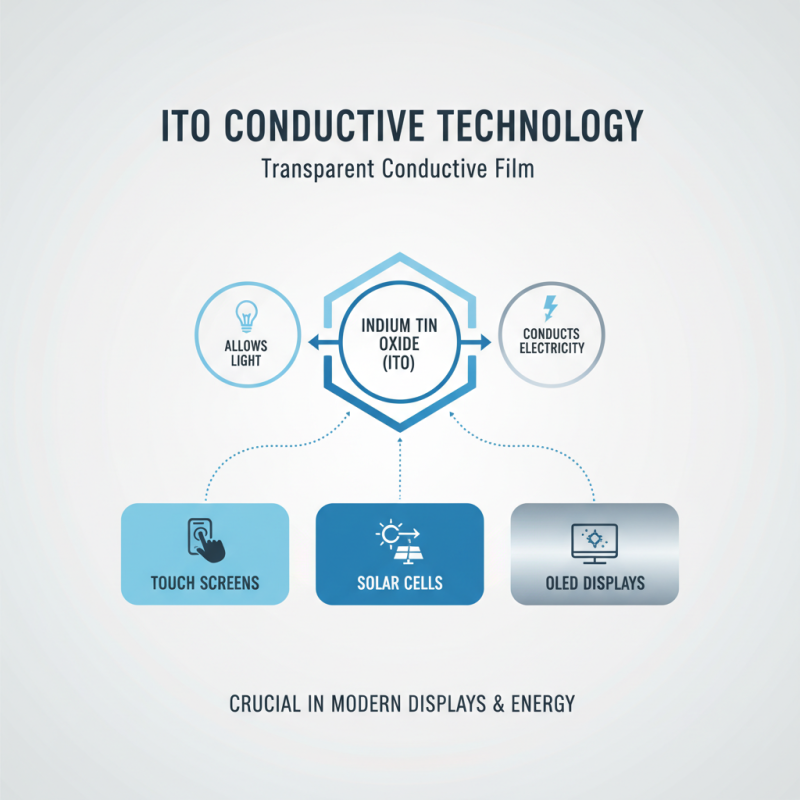

ITO conductive technology, involving indium tin oxide, has become crucial in various industries. It serves primarily as a transparent conductive film. This technology is widely used in touch screens, solar cells, and OLED displays. By allowing light to pass through while conducting electricity, ITO offers unique advantages.

In touch screen applications, users experience immediate response and accuracy. However, the manufacturing process can be complex and costly. Not all regions have easy access to the materials. In solar applications, ITO enhances energy efficiency, but the availability of indium raises concerns about sustainability. Each application has its advantages, but challenges remain.

Exploring alternative materials has gained interest, yet the transition isn't seamless. Conductive polymers and metal meshes show promise but may not meet all performance criteria. Balancing performance, cost, and environmental responsibility is vital for the growth of ITO applications. This technology presents both opportunities and hurdles, prompting ongoing discussion in scientific communities.

Ito conductive materials offer numerous advantages in various modern technologies. They are known for their excellent electrical properties and transparency. This makes them ideal for applications in touch screens, displays, and solar cells. The ability to combine conductivity with visual clarity enhances product design. This synergy is crucial for devices demanding both performance and aesthetics.

When using Ito technology, consider these tips: Ensure proper surface preparation before application. This step can significantly impact adhesion and overall performance. Ambient conditions also matter. Maintaining an optimal environment can reduce defects. Also, always test materials in small batches. This practice allows for adjustments before scaling up.

Taking time to reflect on your processes is essential. Experimenting might lead to unexpected results that can be valuable. Some imperfections may actually open pathways to creativity. Products are better when we embrace a bit of uncertainty. Exploring non-standard methods could yield surprising benefits in the long run.

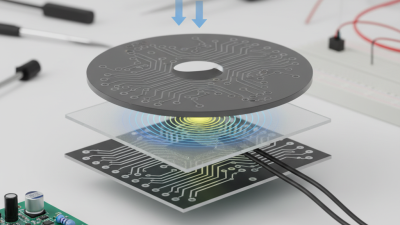

When applying ITO conductive coatings, attention to detail is crucial. Preparation of the substrate is often overlooked. A clean surface enhances adhesion. Dust or oils can lead to performance issues. Research shows that improper cleaning can cause a 30% drop in conductivity. Use solvents that evaporate quickly to avoid residue.

Application methods vary and impact the final quality. Spraying offers even coverage but requires skill. Brushing may introduce air bubbles. Each method has pros and cons. A recent study noted that inconsistent application can reduce the film's uniformity by 20%. Testing small patches before full application is wise. It provides insights into adhesion and transparency.

Proper curing is equally important. Many underestimate the influence of temperature and humidity. Environmental conditions during curing can alter the coating's properties. A controlled environment is ideal. Data indicates that improper curing conditions can diminish conductivity by up to 25%. Time should not be rushed. Balancing these factors can lead to a more successful application. Experimentation can uncover effective techniques, but be prepared for setbacks.

Maintaining ITO conductive surfaces is crucial for their longevity and efficiency. Regular cleaning should be part of your routine. Use a soft, lint-free cloth and a gentle cleanser. Avoid abrasive materials. They can scratch the sensitive surface, reducing its effectiveness. Even minor scratches might compromise its function.

Humidity and temperature play a significant role in the lifespan of ITO surfaces. High humidity can lead to condensation. This moisture can cause short circuits over time. Monitor the environment carefully. Adjusting your workspace conditions might be necessary.

Lastly, handle ITO surfaces with care. They are delicate and can be easily damaged. Use proper tools when installing or adjusting devices. Small mistakes can lead to larger issues. It’s essential to reflect on these points regularly to ensure optimal performance.

This chart displays key maintenance tips for maximizing the lifespan of ITO conductive surfaces, highlighting the recommended frequencies for cleaning, inspecting, and monitoring conditions to ensure optimal performance.

When exploring innovative techniques with ITO conductive technology, understanding its application is vital. ITO films can enhance electronic performance, but application methods can be tricky. Control the deposition speed during the coating process. Faster speeds may lead to uneven layers. This inconsistency can detract from overall performance. Aim for a steady approach for better results.

Using ITO conductive products requires attention to detail. Optimize your substrate preparation. Contaminants can fault the adhesion process. Make sure to clean surfaces effectively. The ideal cleaning method can be a game-changer. Even minor residues can cause significant issues in conductivity.

Take time to experiment with different thicknesses. Sometimes, thinner layers provide better performance. However, achieving this consistent thinness can be challenging. Document the outcomes of your tests. Reflection on what works can direct future methods. Embrace trial and error. Your insights will help shape innovative applications for ITO technology.