A C Shaped Rubber Seal is a versatile component used in many industries. This seal plays a crucial role in maintaining airtight and watertight conditions. It is often used in automotive applications, construction, and appliances. The shape of this seal allows it to fit snugly into grooves, which helps prevent leaks.

These seals can withstand various environmental factors. They resist chemicals, temperature changes, and wear. This durability makes them ideal for long-term use. However, their effectiveness can diminish if not properly maintained. It's important to inspect these seals regularly for signs of wear or damage.

Despite their advantages, C Shaped Rubber Seals are not perfect. They may lose flexibility over time. When installed, they must be fitted correctly to ensure optimal performance. Poor installation can lead to leakage, which defeats the purpose of their use. Understanding the right applications for these seals is essential for achieving desired results.

A C shaped rubber seal is a versatile component found in various industries. These seals are specifically designed to create a barrier against environmental factors such as dust, water, and air. Made from high-quality rubber materials, they ensure a secure fit in mechanical applications. The "C" shape allows for easy installation and removal, making them user-friendly for maintenance.

In automotive and manufacturing sectors, C shaped seals play a crucial role. Research indicates that the global rubber seal market is expected to grow at a CAGR of 5.2% from 2021 to 2028. This growth is fueled by the rising demand for durable sealing solutions. A report highlights that effective seals can reduce energy loss significantly, improving overall system efficiency. Poor sealing can lead to increased wear and tear in machinery, underscoring the importance of quality C shaped seals.

These seals are also adaptable to various applications. For instance, they can be found in doors, windows, and machinery. Properly installed seals can enhance insulation and noise reduction. However, it is common to encounter issues such as misalignment or inadequate compression during installation. These imperfections can reduce their effectiveness, leading to potential leaks and failures. Thus, attention to detail during installation is critical.

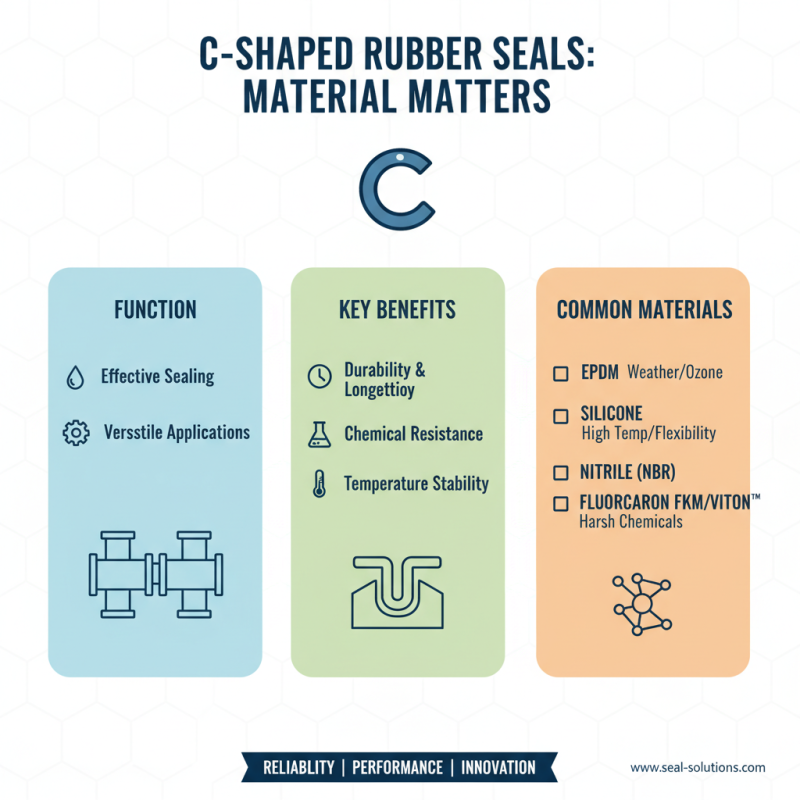

C shaped rubber seals are essential components in various industries. They provide effective sealing solutions for many applications. The materials used in these seals directly impact their performance and reliability.

Commonly, silicone, EPDM, and neoprene are the key materials for C shaped rubber seals. Silicone offers excellent temperature resistance. It performs well in extreme conditions. EPDM is known for its weather resistance. It resists aging and UV rays effectively. Neoprene provides good chemical resistance, making it ideal for automotive uses. Each material has unique properties that suit specific applications.

However, selecting the right material is not always straightforward. Factors such as temperature, exposure to chemicals, and mechanical stress must be considered. Sometimes, trial and error is necessary to achieve the best results. Companies may also overlook the importance of proper installation. A poorly installed seal can lead to leaks and system failures. Attention to detail is crucial for optimal performance.

C shaped rubber seals are widely used in various industries. Their unique design allows for effective sealing in different environments. These seals create a tight barrier against dust, water, and air. This makes them essential for enhancing equipment durability.

One common application is in automotive parts. They are often used around doors and windows. This prevents leaks and reduces noise. Additionally, in HVAC systems, C shaped seals help to improve energy efficiency. They ensure that air does not escape, which is crucial for heating and cooling.

C shaped rubber seals also find their place in electronics. They protect delicate components from moisture and dust. The versatility of these seals means they can be customized for specific uses. However, the performance can vary based on the material. Selecting the right type is vital. Proper installation is equally important to avoid common pitfalls. If not installed correctly, they may lead to failures in sealing.

C shaped rubber seals are essential components in various industries. Their design allows for easy application and effective sealing. The advantages of using C shaped rubber seals are noteworthy. These seals provide excellent durability and resistance to wear and tear. According to industry reports, seals made from high-quality rubber can last up to five years, depending on environmental conditions.

One major advantage of C shaped rubber seals is their flexibility. They can adapt to changes in temperature and pressure. This adaptability lowers the risk of leaks and improves overall performance. Additionally, they help reduce noise and vibrations in machinery. In fact, studies show that proper sealing can decrease operational noise by 20%, enhancing workplace safety and comfort.

Moreover, C shaped rubber seals are cost-effective. They require minimal maintenance and replacement compared to other sealing solutions. This longevity translates to lower operational costs over time. However, one must consider the potential for material degradation due to extreme temperatures or chemical exposure. Regular inspections are necessary to ensure reliability. Operators should not overlook this aspect, as it can lead to unexpected failures. Maintaining the integrity of these seals is crucial for optimal performance.

C shaped rubber seals play a crucial role in various applications. They are commonly found in automotive and industrial sectors. Ensuring their longevity requires proper maintenance and care. Regular inspection is key. Look for signs of wear and tear. Cracks can indicate that a seal is nearing the end of its lifespan. The industry reports suggest that improper maintenance can reduce seal life by up to 30%.

Cleaning is essential. Use mild soap and water. Harsh chemicals can degrade the rubber. After cleaning, dry the seals completely before reinstallation. Moisture can lead to mold growth, which compromises the seal's integrity. Experts recommend applying a manufacturer-approved lubricant occasionally. This will help maintain flexibility and prevent cracking. A simple routine can go a long way.

Temperature fluctuations can impact performance. Be mindful of storage conditions. Extreme heat or cold can cause seals to harden or become brittle. Many overlook this factor, assuming conditions are stable. Regular assessments and adjustments in storage can prevent issues. It's clear: neglect in maintenance can lead to costly repairs down the line. Being proactive can improve the lifespan of C shaped rubber seals significantly.