When it comes to ensuring effective sealing in various applications, choosing the right C Shaped Rubber Seal is critical for the success of your project. These versatile seals play a fundamental role in providing a reliable barrier against dust, moisture, and other environmental factors that could compromise the integrity of your systems. With a myriad of options available in the market, it can be challenging to navigate through different materials, sizes, and specifications to find the perfect fit for your specific requirements.

Understanding the properties of C Shaped Rubber Seals is essential for making an informed decision. Factors such as the intended application, required temperature resistance, and compatibility with various chemicals should all be taken into account. Moreover, the design and installation process can greatly impact the performance of the seal, making it vital to select the correct dimensions and profile. By carefully assessing these elements, you can ensure that the chosen seal not only meets your project's needs but also enhances longevity and efficiency in operation.

In this guide, we will delve into the crucial considerations for selecting the most suitable C Shaped Rubber Seal for your projects, providing insights that will help streamline your decision-making process and enhance the effectiveness of your sealing solutions.

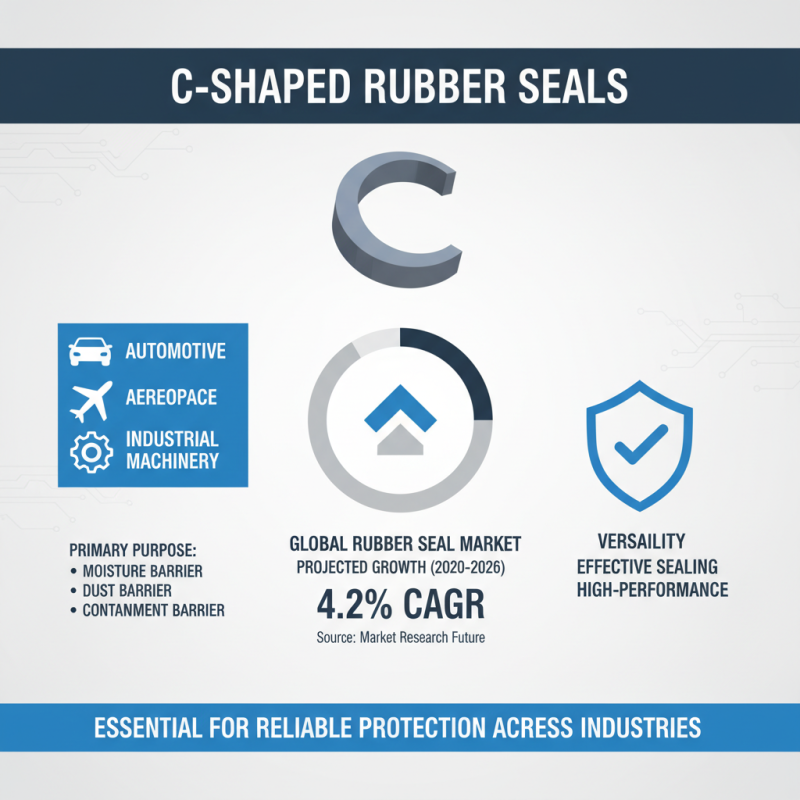

C-shaped rubber seals are widely used in various industries due to their versatility and effective sealing capabilities. Their primary purpose is to provide a barrier against moisture, dust, and other contaminants, making them essential for applications in automotive, aerospace, and industrial machinery. According to a report by Market Research Future, the global rubber seal market is projected to grow at a CAGR of approximately 4.2% from 2020 to 2026, reflecting the increasing demand for high-performance sealing solutions across multiple sectors.

In automotive applications, C-shaped rubber seals play a critical role in ensuring vehicle safety and comfort by preventing water ingress and enhancing sound insulation. They are commonly found around windows, doors, and hoods. A study by the Automotive Sealing Association indicates that effective sealing systems can reduce operational noise levels significantly, contributing to a better driving experience. Moreover, in industrial settings, these seals are integral to maintaining energy efficiency by preventing air leaks in HVAC systems, thus reducing overall energy consumption by up to 30%, as noted in the Energy Efficiency Reports.

Choosing the right C-shaped rubber seal for your project depends on the specific environmental conditions and performance requirements. Factors such as temperature tolerance, chemical resistance, and mechanical strength are crucial to ensuring optimal function. By selecting seals tailored to the exact demands of your application, industries can improve durability and extend the lifespan of their products while achieving lower maintenance costs.

When selecting a C shaped rubber seal for your project, understanding the key specifications and features is essential. First, consider the material type; common options include EPDM, neoprene, and silicone, each offering different levels of durability, temperature resistance, and flexibility. For instance, EPDM is ideal for outdoor applications due to its excellent weather resistance, while silicone is preferred for high-temperature environments. Analyzing the specific conditions in which the seal will be used is crucial in determining the most suitable material.

Another critical specification to evaluate is the cross-sectional dimension of the seal. C shaped rubber seals come in various sizes, and the right choice will depend on the gap you need to fill and the surface compatibility. Ensuring a proper fit helps prevent leakage and enhances the overall performance of the seal. Additionally, pay attention to the hardness of the rubber, measured in durometers. A softer seal might provide a better compressibility and grip, while a harder one will be more durable under mechanical stress. Understanding these features enables you to choose a C shaped rubber seal that aligns perfectly with your project's requirements.

When selecting the right C-shaped rubber seal for your project, evaluating material options is crucial for ensuring both durability and performance. Rubber can come in various formulations, including natural rubber, neoprene, silicone, and EPDM, each offering unique properties that suit different applications.

For instance, neoprene is known for its excellent weather resistance and flexibility, making it ideal for outdoor use, while silicone seals can withstand extreme temperatures, making them suitable for high-heat environments.

Additionally, consider the specific performance requirements of your project. If resistance to chemicals or oils is needed, materials like Viton or Nitrile rubber may be preferable. For applications where high elasticity and compression set resistance are necessary, evaluating the hardness and tensile strength of the rubber is essential. Always check the compatibility of the material with the environment in which it will be used, as this influences not only the lifespan of the seal but also its effectiveness in preventing leaks or providing insulation.

By carefully assessing these material options, you can choose a C-shaped rubber seal that meets the demands of your specific project.

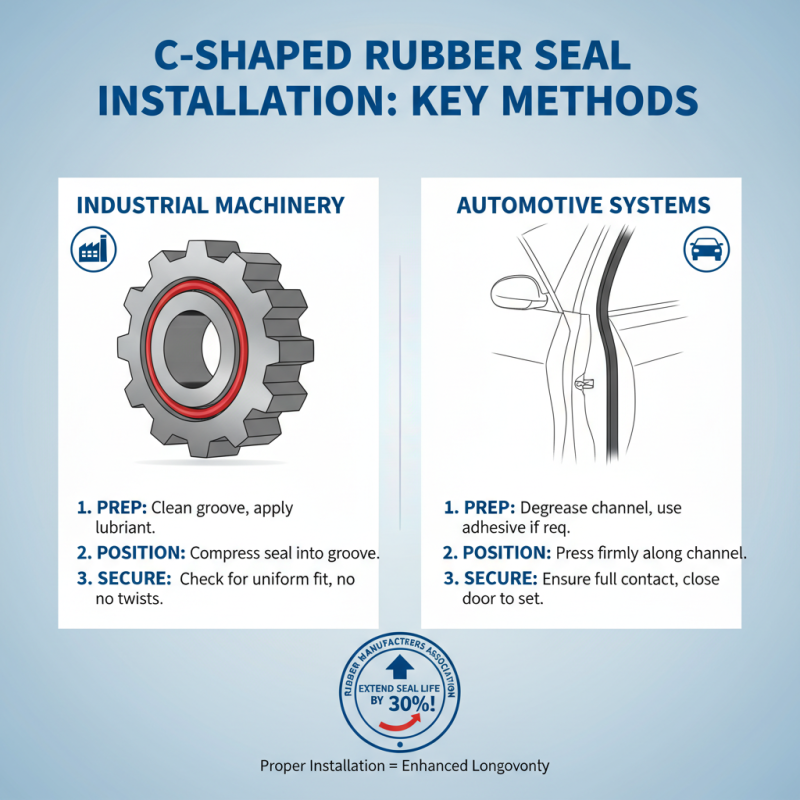

When selecting C-shaped rubber seals for your project, understanding the installation methods is crucial for achieving effective performance and longevity. The installation process can vary significantly depending on the application, whether it be in industrial machinery or automotive systems. According to a recent industry report by the Rubber Manufacturers Association, effective seal installation can enhance the lifespan of sealing solutions by up to 30%, underscoring the importance of getting it right the first time.

Before installation, it is essential to assess the surface conditions where the seal will be applied. A clean, dry surface promotes better adhesion and ensures a proper fit. For installation, methods may include adhesive application or mechanical fastening, depending on the specific requirements of your project. The industry has outlined standard practices that suggest pre-cutting seals to the required length and using appropriate tools to prevent damaging the material during installation.

**Tips:** Always check compatibility with the surfaces and fluids involved. Using a lubricant designed for rubber can facilitate a smoother installation and reduce wear during operation. Ensure to follow manufacturer guidelines for compression settings, which can affect the sealing performance. Being mindful of these factors can make a significant difference in the efficacy of C-shaped rubber seals and the overall success of your project.

When sourcing C-shaped rubber seals for your project, it is imperative to prioritize quality and compatibility with your specific application. According to a report by the International Rubber Study Group, the global demand for rubber seals is expected to grow at a compound annual growth rate (CAGR) of 4.3% through 2026. This growth underscores the importance of selecting the right materials to ensure durability and efficiency in a variety of applications from automotive to industrial machinery.

One key factor in purchasing quality C-shaped rubber seals is understanding the material composition. Different types of rubber, such as EPDM, Nitrile, and Silicone, have unique properties that affect their performance in temperature resistance, chemical exposure, and flexibility. An assessment by the Rubber Manufacturers Association indicates that specifications for rubber material can significantly influence seal performance, leading to a 30% increase in longevity and effectiveness when the appropriate material is chosen.

Additionally, sourcing from reputable suppliers is crucial. Prioritize manufacturers that adhere to industry standards such as ISO 9001, which certifies that they meet quality management requirements. According to a survey by ThomasNet, over 70% of industrial buyers consider supplier certifications as a key factor in their purchasing decisions. By following these guidelines, you can ensure a reliable supply of C-shaped rubber seals that meet your project needs effectively.