Choosing the right Nitrile Rubber Gasket can be challenging. There are many factors to consider. This material is known for its oil and fuel resistance. It performs well in harsh environments. But not all Nitrile Rubber Gaskets are created equal.

When selecting a gasket, the application is crucial. Think about temperature ranges, pressures, and exposure to chemicals. Each parameter can affect the gasket's performance. A mistake here can lead to leaks or failures. Imagine a critical machine part failing due to a poor gasket choice. That's a potential disaster.

Quality matters, too. Look for reputable manufacturers who guarantee their products. Consider durability and flexibility in your selection process. Sometimes, cheaper options might seem appealing. However, they often lack resilience. Reflect on your specific needs before making a decision. It's essential to strike a balance between cost and quality for the best outcome.

When selecting nitrile rubber gaskets, several factors are crucial. The temperature range is one of them. Different applications may subject gaskets to varying temperature extremes. Understanding your operational environment helps narrow down your choices. Consider the chemical compatibility as well. Nitrile rubber can resist many oils, but not all. It's vital to know the specific chemicals that will come into contact with the gasket.

Next, think about the size and thickness of the gasket. These physical characteristics can significantly impact its performance. A gasket that is too thin might not provide a proper seal. On the other hand, an overly thick gasket can create installation challenges. Pay attention to the durometer rating, which indicates hardness. A higher rating means more durability but less flexibility.

Finally, budget constraints are a reality. Choosing the right gasket requires balancing quality and cost. Sometimes, cheaper options can fail sooner than expected. It may lead to additional costs later on. Keep in mind the long-term implications of your initial choice. Conducting thorough research can save you time and effort, even if it feels overwhelming at first.

Nitrile rubber, also known as acrylonitrile-butadiene rubber (NBR), has unique properties that make it ideal for gasket applications. It excels in oil resistance, which is crucial in various industrial settings. This material can withstand high temperatures and maintains its integrity under pressure. However, not all nitrile rubber is the same; the proportion of acrylonitrile affects performance characteristics.

When selecting a nitrile rubber gasket, consider the environmental factors. Temperature fluctuations and chemical exposure play a significant role in gasket performance. A higher acrylonitrile content provides better oil resistance but may limit low-temperature flexibility. Additionally, some gaskets may lack durability when exposed to harsh chemicals. Assess your application to find the right balance.

Tips:

Choosing the right nitrile rubber gasket requires careful consideration. Understand the specific properties that matter most to your application. This will help ensure reliability and longevity in operation, despite potential drawbacks.

When selecting a nitrile rubber gasket, understanding industry standards is crucial. Both ASTM and ISO guidelines provide essential information for ensuring quality and compatibility. ASTM outlines specifications for different applications. ISO standards focus on the general requirements of materials. Adhering to these standards helps in achieving optimal performance and durability.

Tips: Always check if the gasket meets the required specifications for your application. Look for certifications from reputable organizations. Don't overlook environmental factors; they can significantly affect gasket performance.

The right gasket can prevent leaks and save costs. However, improper selection may lead to failure. Consider the temperature and chemical exposure too. Regular testing and evaluation are important. Reflections on past experiences can guide your choice. Aim for improvement.

When selecting a gasket, understanding materials is key. Nitrile rubber offers unique advantages over other options. It excels in oil resistance and durability. This makes it a strong candidate for various applications. However, other materials like silicone and neoprene also have their perks. Silicone gaskets deliver superior temperature resistance but are less effective against oils. Neoprene may be a budget-friendly choice, yet it doesn't match nitrile's performance in harsh conditions.

Tips: Always consider your working environment. Temperature fluctuations can impact the gasket’s lifespan. Evaluate the chemicals it will encounter. This will help prevent premature failures.

While nitrile rubber shines in many areas, it’s not a one-size-fits-all solution. Testing various materials in your specific application is wise. This approach helps identify potential issues before they arise. Analyze how different gaskets perform under stress. Each material tells a story of its own, but the right choice must fit your unique needs.

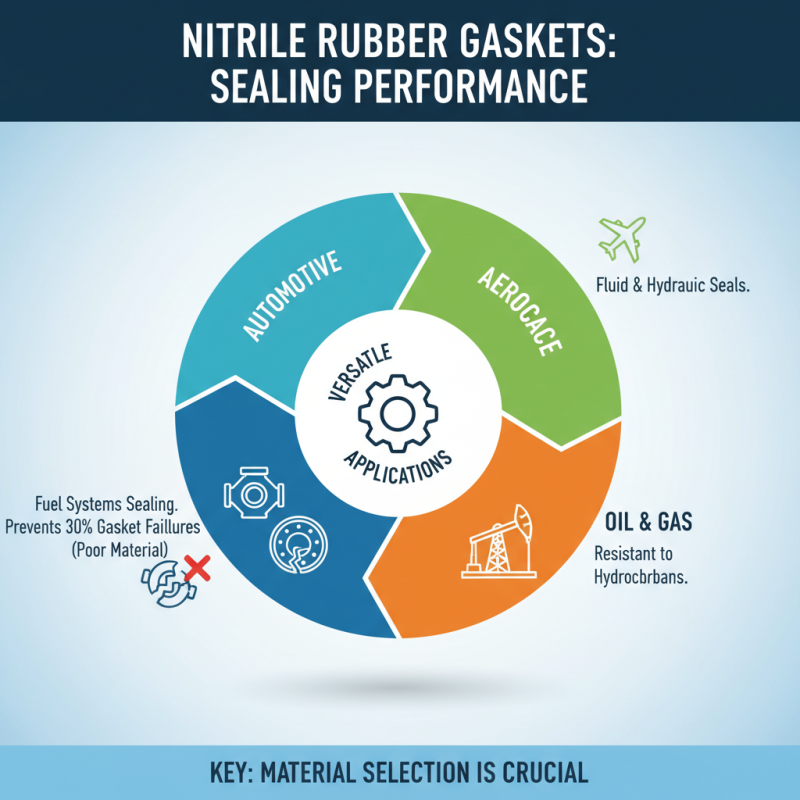

Nitrile rubber gaskets are widely used in various sectors, including automotive, aerospace, and oil and gas. In the automotive industry, they are crucial for ensuring effective sealing in fuel systems. Data indicates that nearly 30% of gasket failures in vehicles are linked to poor material selection. This highlights the importance of choosing the right nitrile compound for specific applications.

In aerospace, these gaskets must withstand extreme temperatures and pressures. A study revealed that gaskets made from high-performance nitrile can endure temperatures up to 120°C. However, many users still overlook compatibility with fuels and oils. This oversight can lead to accelerated degradation of gaskets, causing severe operational issues.

The oil and gas sector relies on nitrile gaskets for their resilience in harsh environments. Reports indicate that improper installation can reduce a gasket's lifespan by up to 50%. This points to the necessity of proper training and awareness among workers. There is still room for improvement. Investing in high-quality installation practices is crucial for optimizing performance and extending the life of these gaskets.