When it comes to selecting the right C Shaped Rubber Seal for your project, expert opinions are invaluable. John Smith, a seasoned engineer in the sealing solutions industry, emphasizes, “Choosing the right seal can make or break your project.” Understanding the details involved in this decision is crucial.

C Shaped Rubber Seals are versatile. They serve various applications, from automotive to industrial settings. Their design allows for effective sealing while accommodating slight movements. However, choosing the wrong type can lead to leaks and costly repairs. It’s easy to overlook specific requirements like temperature resistance and material compatibility.

Different projects have unique needs. A seal suitable for one situation may not work for another. Consider the environment where the seal will be used. Moisture, chemicals, and temperature fluctuations all affect performance. Reflecting on these factors can help in making a more informed choice. Remember, the right C Shaped Rubber Seal is not just about the product; it's about ensuring it aligns with your project's demands.

C-shaped rubber seals are versatile components used in various industries, from automotive to construction. Their design allows for effective sealing, which reduces leakage and improves efficiency. According to a report by the International Rubber Study Group, the demand for rubber seals, including C-shaped ones, is expected to grow by 3.5% annually. This trend highlights the importance of selecting the right type for specific applications.

Different types of C-shaped seals cater to various needs. For instance, closed-cell seals offer excellent thermal insulation properties, while open-cell versions allow for airflow. A study by the American Society for Testing and Materials (ASTM) emphasizes that using the correct seal type can decrease operational failures by 15%. Users often overlook this aspect, leading to inefficiencies in their projects.

Material choice also plays a crucial role. High-quality rubber types such as EPDM and silicone each have distinct advantages. EPDM resists weathering, while silicone withstands high temperatures. Many users may not fully understand these differences, which can result in costly errors. Awareness of the specific conditions that seals will face can lead to better project outcomes.

When selecting C shaped rubber seals, several key factors come into play. Material selection is crucial. Different rubber compounds offer varying levels of durability and flexibility. According to a report by the Rubber Manufacturers Association, high-grade synthetic rubber outperforms natural rubber in harsh environments, making it suitable for industrial applications. Your choice should reflect the specific demands of your project.

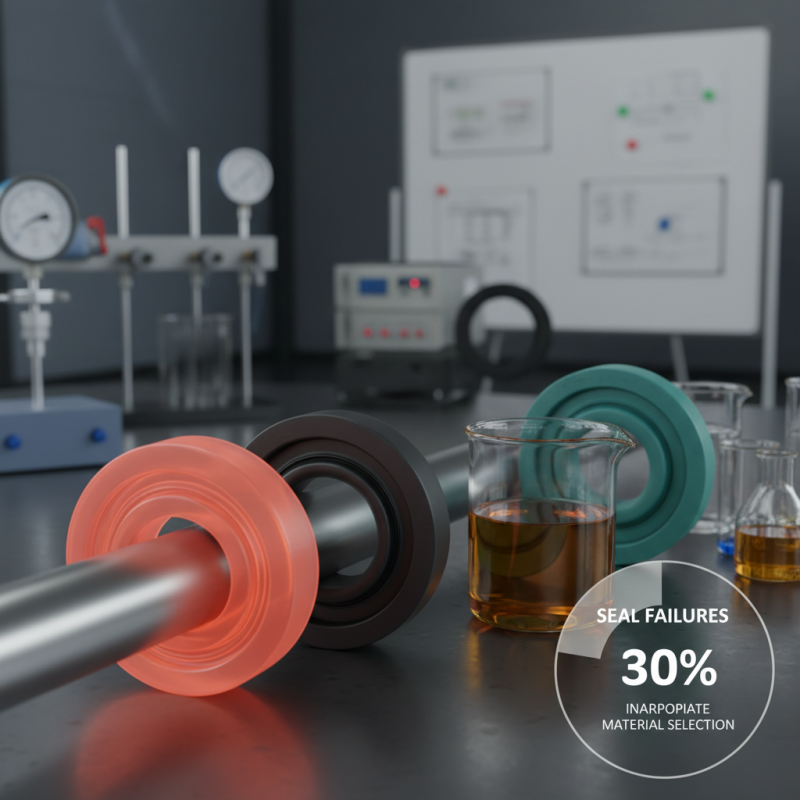

Another important factor is the seal's dimensions. Accurate measurements are vital to ensure a proper fit. An ill-fitting seal can lead to leaks or failures, wasting resources and complicating maintenance. Data indicates that 30% of sealing failures are due to incorrect dimensions. Therefore, always double-check your measurements before making a decision.

Consider the environmental conditions where the seal will be used. Factors like temperature, exposure to chemicals, and moisture levels can significantly impact performance. A seal that works well in one scenario might degrade quickly in another. Regular assessments and adaptations are necessary as conditions evolve. Make sure to reflect on your specific requirements and test prototypes whenever possible for optimal performance.

When selecting a C shaped rubber seal, understanding the material options is essential. Common choices include

silicone, EPDM, and neoprene.

Silicone, for instance, offers excellent temperature resistance. It can withstand extreme heat and cold. However, it is not as durable when exposed to certain chemicals.

EPDM is another strong contender. It excels in outdoor environments and resists UV rays. Yet, it may not perform well in higher temperatures.

Neoprene is versatile and often used in various applications. It resists oils and chemicals effectively. However, neoprene can become brittle over time, especially in harsh weather.

Each material has its strengths and weaknesses. Sometimes, making the wrong choice can lead to failure in your project.

This is where careful consideration comes into play. Testing different materials can be helpful. If possible, request samples before committing to a large order.

This way, you can see how they hold up under specific conditions. Adjust your selection based on your observations. It may take time, but finding the right seal is worth the effort.

Choosing the right C shaped rubber seal starts with proper sizing and dimensioning. Accurate measurements are crucial for an optimal fit. Begin by measuring the groove where the seal will be placed. Ensure you get the width and depth. A seal that's too thick may not fit properly. On the other hand, a seal that is too thin won't provide adequate sealing.

Tips: Always use calipers for precise measurements. They help you avoid guesswork. If possible, consult with an expert on the required dimensions. Some projects may need specialized seals. Also, remember that environmental factors, such as temperature, can impact seal performance.

Don't overlook the material properties. Different rubber compounds have varying hardness and flexibility. A soft rubber may deform easily but could wear out faster. You might need a firmer seal for better longevity. This balance is often difficult to achieve. It requires testing and adjustments.

Tips: Consider ordering samples before making a bulk purchase. This allows you to test fit and functionality. Be clear about your project’s specific needs, which can guide your choice. It’s important to reflect on all factors to make an informed decision.

Choosing the right C shaped rubber seal involves careful consideration. Many professionals make critical mistakes that could easily be avoided. One common error is not analyzing the application environment. Different conditions require different materials. For instance, high heat might demand silicone rubber, while oil resistance needs specific EPDM compounds. According to industry reports, nearly 30% of seal failures stem from inappropriate material selection.

Another frequent blunder is ignoring seal dimensions. It's essential to measure accurately. Seals that are too tight can fail prematurely. Conversely, loose seals may not perform adequately, leading to leaks. A survey indicated that 25% of users faced significant issues due to improper sizing of seals.

Tips: Always refer to manufacturer specifications for precise dimensions. Understand the environmental factors impacting your choice, such as temperature and chemicals. Lastly, evaluate your project's long-term needs to avoid unnecessary replacements in the future. Prioritize quality and compatibility over cost to save money in the long run.