When embarking on a project that requires rubber gaskets, selecting the right Rubber Gasket Silicone is crucial. According to a recent report by the Silicone Institute, the market for silicone gaskets is projected to grow by 5% annually. This growth indicates a rising demand for quality materials in various industries, including automotive and construction.

Expert John Smith, a leading figure in gasket technology, emphasizes, "Choosing the right Rubber Gasket Silicone can make or break a project." His insights highlight the importance of not only the material's durability but also its compatibility with specific applications. Many professionals overlook these factors, leading to expensive failures.

Additionally, the variety of rubber compounds can be overwhelming. Each type has its strengths and weaknesses. Projects may suffer if the wrong silicone is chosen. Prioritizing the right specifications can enhance the longevity and efficiency of your application. Sometimes, it’s the small details that lead to significant impacts in performance and reliability.

Rubber gasket silicone materials are vital for many projects. These materials provide sealing solutions in various industries, including automotive and plumbing. Understanding their properties is essential to ensure you choose the right type. Rubber gasket silicone is flexible yet durable. It can withstand both high temperatures and varying environmental conditions.

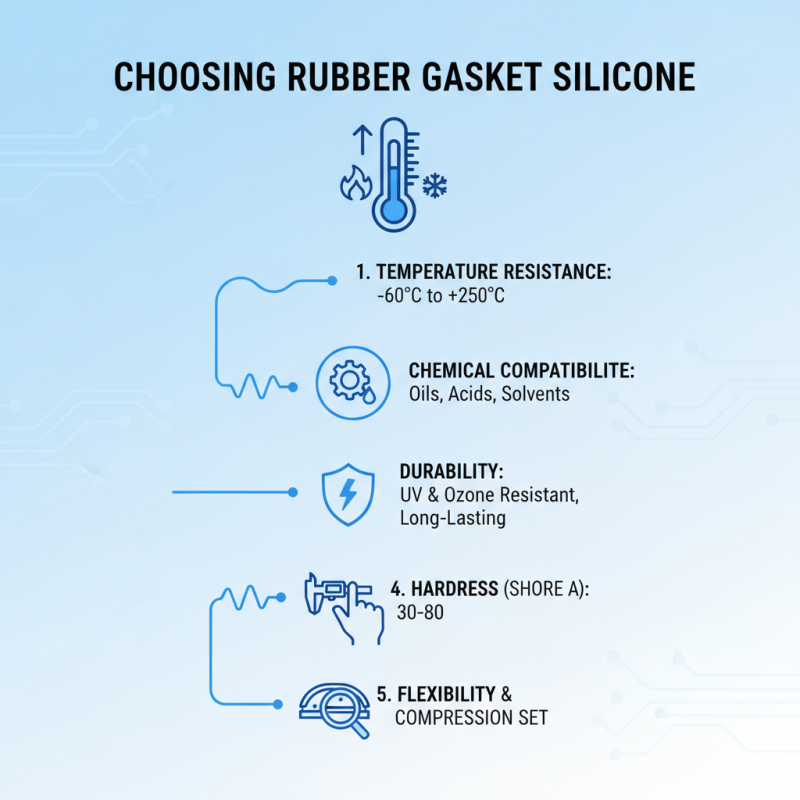

Selecting the appropriate silicone involves recognizing its hardness and temperature tolerance. A suitable Shore A hardness can enhance sealing performance. Many users overlook these properties and face issues. The struggle often lies in finding a balance between flexibility and strength. Take the time to conduct a thorough analysis of your needs before making a decision.

Another crucial aspect is the environment where the silicone will be used. Some applications require resistance to chemicals or UV exposure. Ignoring these factors may result in premature failure of the gasket. Engage in discussions with experts or peers who have faced similar challenges. Their insights can lead to better choices and save future headaches. Understanding the basics can significantly impact your project's success.

Choosing the right rubber gasket silicone for any project is crucial. There are several key properties to consider. First, the temperature resistance of the silicone is vital. Ensure it can withstand the temperatures your project may encounter. If it cannot handle high heat, it will fail prematurely.

Another important aspect is the chemical resistance of the silicone. Different projects may expose the material to harsh chemicals. Selecting a silicone that can resist degradation from these substances is key. For example, gaskets used in oil applications must withstand corrosive conditions.

Additionally, consider the hardness of the silicone. Softer materials may compress easily, but they could wear out faster. Harder materials typically last longer, but they might not seal well in certain applications. Weigh the pros and cons based on your specific needs. Make sure to test your choice in real-world conditions. This can reveal weaknesses that may not be apparent at first. Even small variations in material can lead to significant issues.

When selecting rubber gasket silicone, understanding temperature and chemical resistance is crucial. Most silicone gaskets can handle temperatures between -60°F and 450°F, but this varies. For instance, high-performance silicone can withstand up to 500°F. It's critical to refer to manufacturer specifications to ensure compatibility with your project needs.

Chemical resistance also plays a significant role. Silicone gaskets generally resist water, UV radiation, and different common solvents. However, they might degrade when exposed to strong acids or bases. According to industry reports, silicone gaskets can experience a reduction in tensile strength when exposed to certain chemicals over time. It's wise to conduct tests for specific applications to verify their limits.

As you evaluate these aspects, remember there isn't a one-size-fits-all solution. Each project may require unique parameters. Analyze the environment and conditions in which the gaskets will be used. Ignoring these variables might lead to premature failure or costly downtime. Researching and testing various options allows for better decision-making. Pay attention to the nuances that could impact performance.

| Tip | Description | Temperature Resistance (°C) | Chemical Resistance |

|---|---|---|---|

| 1 | Select suitable silicone based on project needs. | -60 to 230 | Excellent resistance to water, ozone, and UV. |

| 2 | Consider the working environment and conditions. | -40 to 200 | Good resistance to acids and bases. |

| 3 | Check for FDA approval for food applications. | -50 to 180 | Resistant to many food oils and fats. |

| 4 | Evaluate the durometer hardness for sealing requirements. | -50 to 205 | Resistant to various solvents and chemicals. |

| 5 | Look for thermal stability for high-temperature applications. | -60 to 260 | Resistant to corrosion and oxidation. |

| 6 | Assess the compression set for long-term applications. | -40 to 230 | Good resistance to thermal and mechanical stress. |

| 7 | Verify compatibility with other materials in the assembly. | -60 to 210 | Resistant to fuels and oils. |

| 8 | Identify if the gasket will be exposed to high pressure. | -50 to 225 | Excellent mechanical abrasion resistance. |

| 9 | Determine if color coding is necessary for your application. | -60 to 220 | Good resistance to weathering effects. |

| 10 | Evaluate the overall cost-effectiveness of the chosen silicone. | -45 to 210 | Resistance levels vary by formulation and use. |

When selecting rubber gasket silicone, it is crucial to understand the various types available and their applications. Silicone rubber is known for its thermal stability and flexibility. This makes it suitable for diverse industries like automotive, aerospace, and food processing. According to a recent market report, the silicone rubber market is projected to reach $8 billion by 2025, emphasizing its growing significance.

Different types of rubber gasket silicone offer unique properties. High-temperature silicone withstands extreme environments, ideal for engine components. On the other hand, low-temperature silicone remains pliable in colder climates. A study published in the Journal of Materials Science highlights that proper selection can reduce gasket failure by up to 25%. This statistic stresses the importance of matching the right silicone type to project conditions.

However, the abundance of options can lead to confusion. Many users might overlook specific requirements or end up with unsuitable materials. Companies often underestimate the impact of environmental factors such as ozone exposure or moisture. Recognizing these elements can be a game changer. This awareness enhances the longevity and effectiveness of silicone gaskets in various applications. Always remember the potential for miscalculation can result in increased costs and project delays.

Choosing the right rubber gasket silicone is crucial for any project. Proper installation and maintenance can extend the life of your gaskets. Studies show that improper installation is a leading cause of gasket failure, accounting for over 30% of issues. This highlights the need for best practices in handling these components.

Ensuring a clean surface is vital. Dirt and debris can compromise the seal. A clean environment minimizes the risk of contamination. Apply the gasket adhesive evenly. This helps achieve a uniform seal. Remember to allow adequate curing time after installation. Rushing this step can lead to leaks.

Regular maintenance is key. Inspect gaskets periodically for signs of wear, such as cracks or degradation. Don't overlook environmental factors. Heat or chemicals can accelerate gasket wear. Use the right lubricants and avoid excessive force when tightening. Studies emphasize managing installation pressure. Too much pressure can lead to leaks and failures in the long run. Investing time in these practices will ensure better performance and longevity for your rubber gaskets.