In today’s advanced industrial landscape, understanding Thin-Film Pressure Sensors is crucial. Renowned industry expert Dr. Emily Carter emphasizes, “Effective use of Thin-Film Pressure Sensors hinges on proper calibration and environmental awareness.” This highlights the importance of thoughtful application in various settings.

Thin-Film Pressure Sensors offer remarkable precision. Their compact design allows them to be integrated into intricate systems. However, users often overlook the effects of temperature and moisture on sensor performance. Neglecting these factors can lead to inaccurate readings.

Moreover, familiarity with the sensor’s specifications is vital. Each application demands unique understanding and adjustments. Mistakes in setup can result in significant performance loss. It’s essential to continuously learn and adapt techniques for optimal efficiency. Thin-Film Pressure Sensors present opportunities for innovation but require careful consideration for best results.

Thin-film pressure sensors are crucial for various applications. Their design is based on thin layers of materials that respond to pressure changes. This technology is used in automotive, aerospace, and medical fields. The sensors provide high sensitivity and accuracy, making them popular in industrial environments.

One effective tip is to consider the mounting method. Ensure the sensor is securely fixed to avoid measurement errors. Poor installation can lead to inaccurate readings. Regular calibration is also important. It helps maintain sensor performance over time. This is something many users often overlook, yet it is essential for reliable data.

Another tip involves understanding the environmental conditions. Thin-film sensors can be affected by temperature and humidity. Operating them outside their specified limits can result in failure. Always check the specifications before use. This precaution helps in achieving better results and enhances longevity.

Choosing the right thin-film sensor significantly impacts performance. Start by identifying the pressure range necessary for your application. Too high or too low a range can lead to inaccurate readings. Consider environmental factors as well. Some sensors perform poorly in extreme temperatures or humidity.

Next, look at the material compatibility. Certain sensors may not endure corrosive substances. This can lead to sensor failure. Review installation requirements. A poorly installed sensor can result in unreliable data. Ensure alignment; misalignments can skew pressure readings.

Research the resolution and accuracy you need. Some applications demand higher precision than others. Don’t forget about calibration. Regular checks can prevent drift over time. An overlooked aspect is the sensor’s response time. In fast-paced environments, a slow sensor can lead to critical delays.

When installing thin-film pressure sensors, optimal performance hinges on several key guidelines. Start by considering the mounting surface. It should be clean and flat. A rough surface can introduce errors. According to industry data, improper installation can lead to a 15% decrease in accuracy. This highlights the need for precision during setup.

Environmental factors play a crucial role as well. The temperature range should match the sensor’s specifications. Exceeding these ranges can result in drift or failure. For reference, 45% of reported issues stem from environmental mismanagement. Flexible wiring is also vital. It prevents tension that can compromise readings, as stressed wires can lead to misleading pressure data.

Finally, regular calibration is essential. A study shows that routine checks can improve reliability by 30%. Neglecting calibration may cause deviations over time. While guidelines exist, practical applications often reveal unexpected challenges. A sensor may perform well in theory, but real-world factors can vary significantly. Reflection on past installations can improve future outcomes.

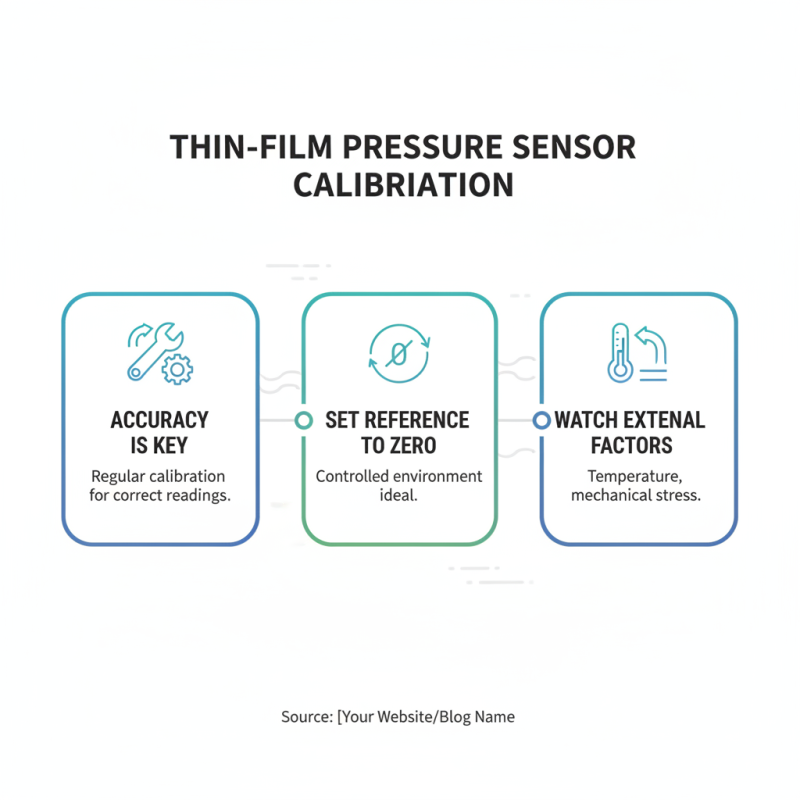

Calibration is critical for achieving accurate readings with thin-film pressure sensors. Regularly calibrating the sensors ensures they function correctly. It's essential to set the reference pressure to zero. This is often done in a controlled environment. However, external factors can affect readings, such as temperature fluctuations or mechanical stress.

To begin calibration, use a known reference pressure source. Gradually apply varying pressures and record the sensor's response. Compare this against the reference pressure. Adjust the sensor output as needed. Sometimes, results can be inconsistent, requiring a rethink of the initial setup. Calibration drift is common. Regular checks can help maintain accuracy.

Maintaining proper records of calibration sessions enhances reliability. Documenting the conditions during calibration can help identify patterns or anomalies. Even minor changes can impact results. Continuous evaluation is vital, as environments change over time. Regular reflection on the calibration process helps improve accuracy and sensor longevity.

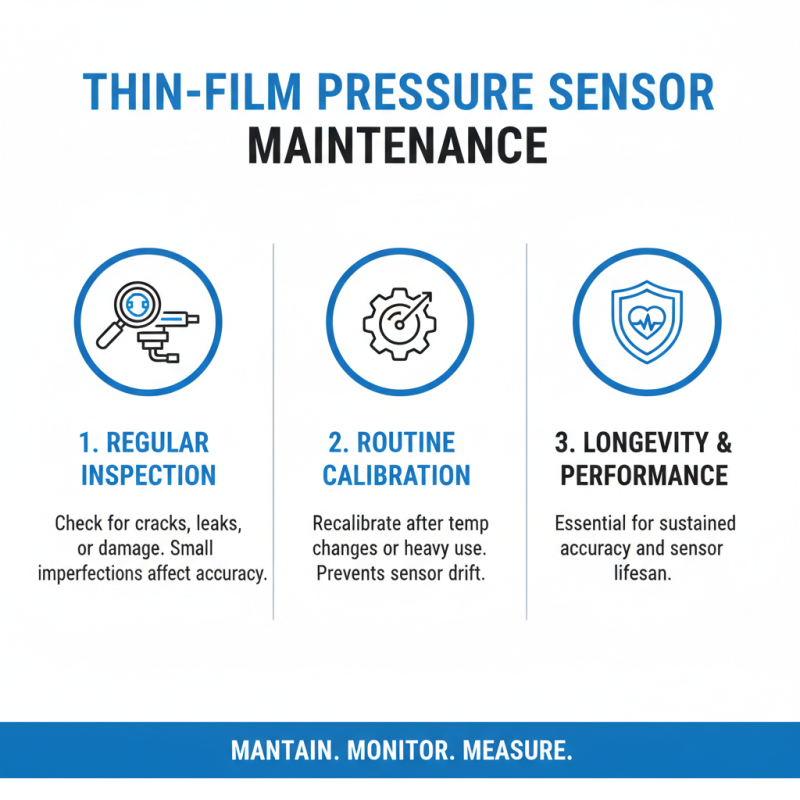

Maintaining thin-film pressure sensors is essential for their longevity and performance. Regular inspection is crucial. Check for any signs of damage, like cracks or leaks. These small imperfections can significantly impact accuracy. Routine calibration is also necessary. Sensors may drift over time, affecting readings. Make it a habit to recalibrate after significant temperature changes or heavy use.

Environmental factors play a significant role in sensor lifespan. Keep sensors clean and free of dust. A buildup can obstruct readings. Ensure they operate within specified temperature and humidity ranges. Exposing sensors to extreme conditions can lead to premature failure. Sometimes, despite precautions, issues arise. Not all sensors respond well to certain chemicals, which can degrade materials. Understanding the specific environment can enhance your approach.

Consider proper installation techniques. Incorrect mounting can introduce stress, leading to inaccurate measurements or damage. Review your installation methods periodically. Make adjustments as necessary. Documenting maintenance activities can also provide valuable insights. If problems occur, refer to past actions for better understanding. This helps to improve future practices. Regular reflection on these processes ensures better performance over time.