Choosing the right Embossed Membrane Keypad can significantly impact project success. According to a report by Global Market Insights, the demand for these keypads is expected to grow by 7% annually until 2026. This increasing trend highlights the importance of making informed choices when selecting a keypad.

Industry expert Dr. Michael Thompson emphasizes, "Every project requires unique features; choosing the right keypad should address specific needs." His insight urges designers to consider functionality alongside aesthetics. High-quality materials, durability, and user interface are essential. However, not all manufacturers provide reliable products. Careful evaluation is crucial to avoid potential pitfalls.

The diversity in design options can be overwhelming. Some may overlook the keypad’s usability, focusing solely on appearance. Functionality often needs to align with the project's overall vision. Investing time in research can lead to more effective and user-friendly designs. The journey is complex but rewarding when the right Embossed Membrane Keypad is chosen.

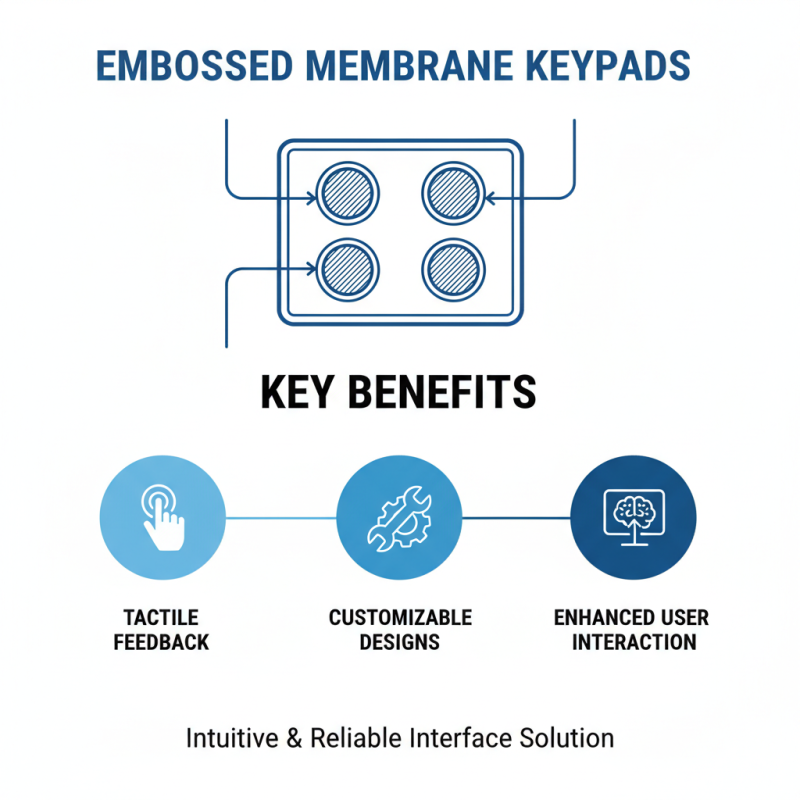

Embossed membrane keypads are a popular choice for various applications. They provide tactile feedback, which enhances user interaction. These keypads can be customized with different textures and designs. This is crucial for creating an intuitive experience.

Understanding their features is vital before making a decision. The thickness of the membrane impacts durability and feel. Thicker membranes may last longer but could compromise flexibility. Key pads can also be backlit, enabling visibility in low-light situations. Think about how your project will be used. Will it be exposed to moisture or dust? These conditions can affect the membrane's performance.

Consider the adhesive used in the keypad's construction. A strong adhesive ensures longevity and reliability. However, sometimes it can be a challenge to peel off. This may lead to rework or higher replacement costs. Take the time to weigh these factors. Each choice shapes the user experience. Choosing the right embossed membrane keypad involves introspection and foresight.

When selecting an embossed membrane keypad, the choice of material is pivotal. Polycarbonate and polyester are popular options for their durability and flexibility. According to industry reports, polycarbonate keypads show a 15% higher resistance to abrasion compared to polyester. This can be crucial for devices subject to heavy use. However, polycarbonate's susceptibility to UV damage may require thoughtful placement and usage scenarios.

Design is equally important. Keypad layout impacts user experience significantly. Studies indicate that efficient design can improve user interaction by up to 25%. A well-designed keypad must consider tactile feedback and visual clarity. The use of tactile enhancements can aid users, making the keys more intuitive. Overlooking these elements can lead to user frustration. It’s essential to balance aesthetics with functionality.

Lastly, consider environmental factors. Some materials degrade faster in harsh conditions. For example, certain adhesives weaken in high humidity. Choosing a keypad that combines durability with the right adhesive can prolong the lifespan of your product. This balance is not always easy to achieve, leading to potential reflections on design choices. The key is to evaluate all aspects carefully to avoid future complications.

| Consideration | Details |

|---|---|

| Material | Polyester, Polycarbonate, PVC |

| Thickness | 0.5 mm to 1.5 mm |

| Key Texture | Embossed, Smooth, Textured |

| Design Customization | Colors, Logos, and Labels |

| Durability | Chemical Resistance, UV Stability |

| Operational Temperature | -20°C to 70°C (-4°F to 158°F) |

| Installation Method | Adhesive, Snap-fit, or Embedded |

| Backlighting Options | LED, Electroluminescent, or None |

Durability and lifespan are crucial when choosing an embossed membrane keypad. These keypads are often used in demanding environments. Factors such as temperature, humidity, and mechanical wear greatly affect their performance. A keypad that doesn’t withstand these conditions will quickly fail, leading to costly repairs.

When assessing durability, consider the materials used in the keypad construction. High-quality substrates, such as polyester and polycarbonate, offer better resistance to wear and tear. However, even with robust materials, issues like adhesive delamination can occur over time. Regular testing under ideal conditions may not reveal potential failures in real-world scenarios.

Lifespan also hinges on use frequency and user interaction. Membrane keypads receive different levels of pressure and usage in various applications. Testing them under typical usage conditions helps gauge their true longevity. This evaluation should consider user habits. Ultimately, understanding these factors leads to better selection and can prevent unexpected failures in your project.

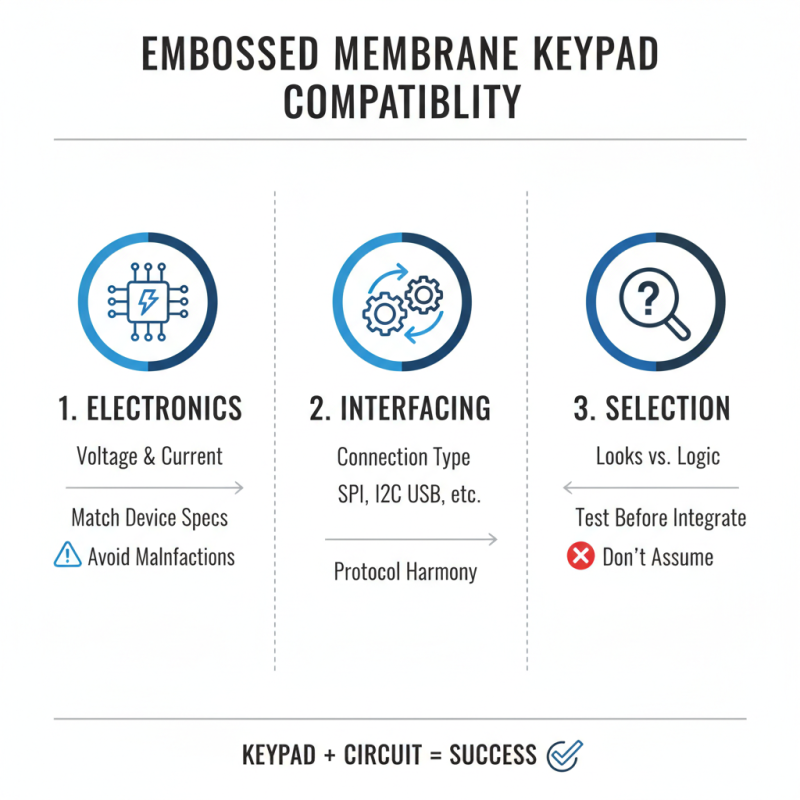

When selecting an embossed membrane keypad, compatibility with your project's electronics is crucial. Different devices require various interfacing methods. Ensure you understand the voltage and current requirements of your electronics. This will help you avoid potential malfunctions. Sometimes, a keypad can look ideal but is incompatible with your circuitry.

Pay attention to the communication protocols that your project uses. Many keypads operate on specific signals such as I2C or SPI. This directly influences their compatibility. You might find that the keypad doesn't communicate properly with the microcontroller. Check that the keypad can connect seamlessly with your existing components.

Also, consider the keypad's layout and size. If it doesn’t fit your device's design, it'll be a challenge. Measure the space available precisely. Errors in measurement can lead to impractical installations. Test the keypad with a prototype before making a final decision. This can save you time and resources. The process may feel tedious, but it ensures your project runs smoothly.

Budgeting for an embossed membrane keypad project can be tricky. Various factors influence the cost. These include materials, design complexity, and production volume. Costs can quickly add up if not planned carefully.

Start by assessing the project's requirements. Define your features and specifications. More complex designs usually mean higher expenses. Consider the material quality as well. Cheap materials might save money but could lead to durability issues. Weighing cost versus quality is crucial.

Don't forget about prototyping costs. A prototype is essential but can be an additional expense. Factor in testing and revisions too. Sometimes, the initial design may require adjustments. These can inflate your budget unexpectedly. It's wise to have a buffer for such cases. Also, remember ongoing maintenance costs down the line.