Nitrile O Rings are essential components in various industries. They provide seals in machinery, preventing leaks and enhancing performance. According to recent reports, the global market for O rings is expected to reach $1.7 billion by 2026, driven by demand in automotive and aerospace sectors.

These rings are made from nitrile rubber, known for its oil resistance and durability. Nitrile O Rings are widely used in hydraulic systems, pumps, and engines. This versatility makes them invaluable for manufacturers aiming to achieve reliability. However, not all Nitrile O Rings are created equal. Variations in formulation can impact their performance and lifespan.

Engineers must carefully select the type for each application. Misjudgment can lead to failure, loss of efficiency, and costly repairs. It's crucial to understand the specific conditions under which these O Rings will operate. As the market grows, awareness of material properties becomes increasingly important. Nitrile O Rings aren’t just components; they represent a balance of innovation and practical application.

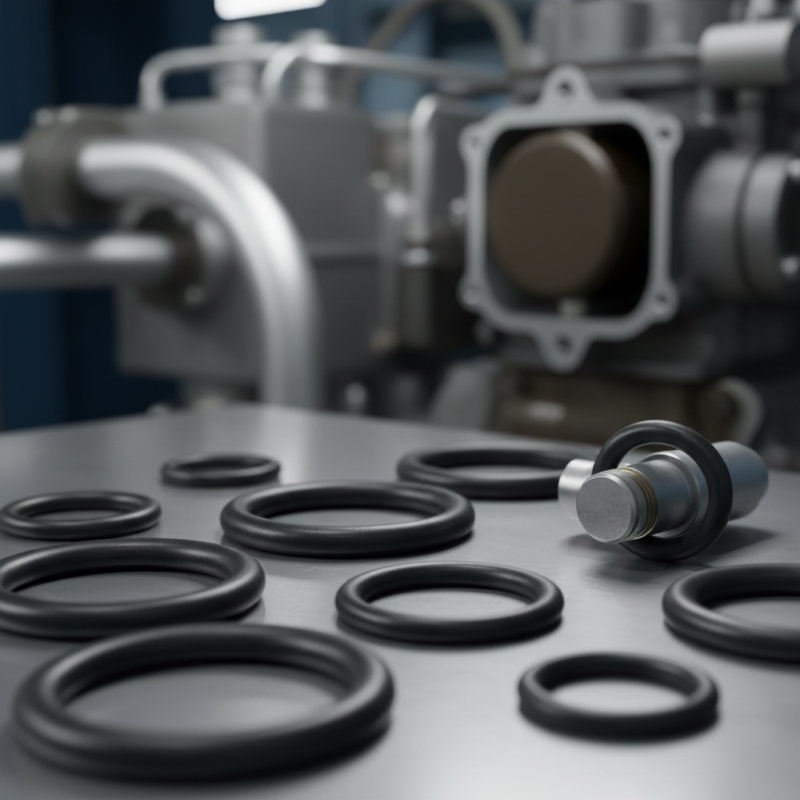

Nitrile O rings are essential components in various mechanical applications. They are circular seals made from nitrile rubber, known for its excellent resistance to oils and fuels. This makes them popular in automotive and aerospace industries. Their ability to withstand high pressures and temperatures adds to their versatility.

These O rings act as barriers to prevent leaks in systems such as hydraulic cylinders and pneumatic equipment. When properly installed, they can effectively seal gaps, ensuring that fluids do not escape. Their effectiveness, however, can be compromised if they are not the right size or if they are exposed to extreme conditions.

Considering their importance, it’s crucial to assess the right material and design for each specific application. Some users might overlook this detail and face leakage issues as a result. It’s a reminder that even small components can impact overall performance. Choosing the correct Nitrile O rings requires careful thought.

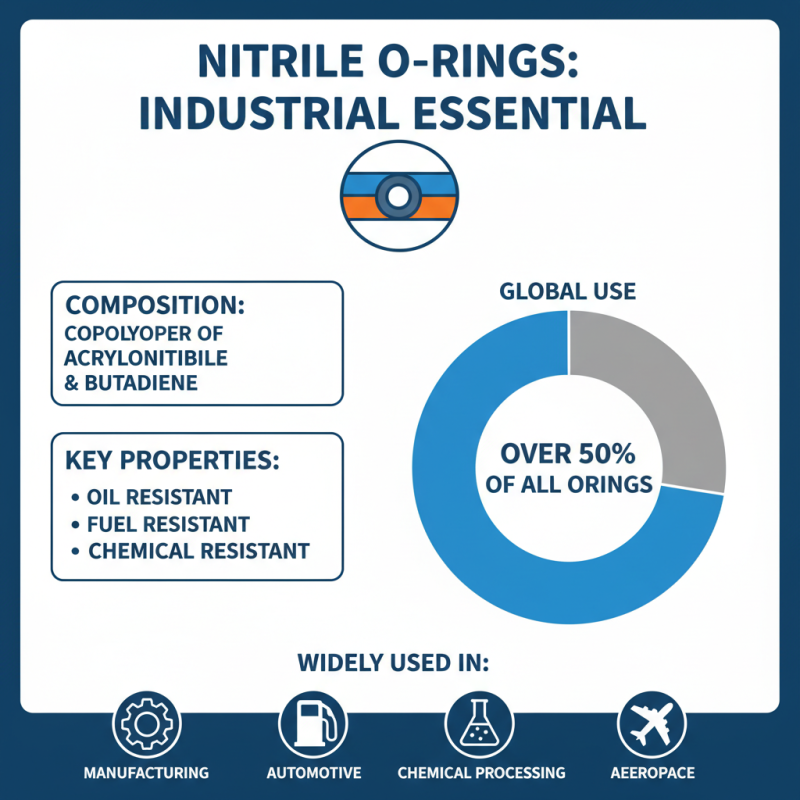

Nitrile O rings are widely used in various industries. Their main composition is a copolymer of acrylonitrile and butadiene. This unique combination results in a material that is resistant to oils, fuels, and numerous chemicals. According to industry reports, over 50% of O rings produced globally are made from nitrile rubber.

The properties of nitrile O rings make them ideal for sealing applications. They offer great wear resistance and can perform in a temperature range from -40°C to 100°C. In fact, certain formulations withstand even higher temperatures. However, they may not be suitable for use in ozone-rich environments. This limitation can be critical in some applications.

Nitrile O rings exhibit an impressive tensile strength of up to 20 MPa, yet there are instances of premature failure if improperly installed. Proper sizing and installation are essential. Most users overlook these details, which can lead to costly leaks. Even with ideal conditions, nitrile O rings have the potential to degrade over time. Regular inspection is vital to ensure optimal performance.

Nitrile O rings are widely used in various industries due to their excellent sealing capabilities. They are made from a synthetic rubber material known as nitrile. This material is known for its resistance to oils, fuels, and other chemicals. Thus, it's ideal for applications where exposure to these substances is common.

One typical application is in automotive engines. Nitrile O rings effectively seal engine components, preventing leaks that could lead to significant damage. In hydraulic systems, they are crucial for maintaining pressure and fluid containment. They can withstand extreme temperatures, making them suitable for both high and low-temperature environments.

Despite their strengths, nitrile O rings can wear out over time. They may degrade in the presence of certain chemicals, especially at high temperatures. Users must regularly inspect and replace these O rings to ensure optimal performance. Without proper maintenance, even the best O rings can fail, leading to costly repairs. It’s vital to consider the specific conditions in which they will be used to avoid premature failure.

Nitrile O rings are essential components in various applications. They are known for their durability and resistance to oils and fuels. Proper installation and maintenance are crucial for their optimal performance.

When installing nitrile O rings, it’s important to ensure a clean surface. Dirt or debris can lead to failure. Apply a thin layer of lubricant to the ring before installation. This helps in achieving a good seal. However, avoid over-lubrication as it might cause slippage. Pay attention to proper sizing; a ring that is too small will stretch, while one too large will not seal effectively.

Regular maintenance checks are necessary to identify any wear or damage. Inspect for cracks or deformation. Over time, O rings may harden or lose their elasticity. If you notice signs of aging, it’s time for a replacement. Neglecting this step can lead to leaks. Keeping spare rings on hand is a practical approach. It avoids disruption when failures occur. Remember, a small oversight in maintenance can lead to bigger problems down the line.

Nitrile O rings are popular in various applications. They offer several advantages. Nitrile is resistant to oil and fuel. This makes them ideal for automotive and industrial use. They can withstand a wide temperature range, from -40°C to 120°C. Their durable nature ensures longevity in many environments. However, they do have limitations. Nitrile is not ideal for extreme temperatures above 120°C.

Consider that nitrile can degrade in direct sunlight. O rings may swell in certain solvents. This can lead to failure in specific applications. Users must be cautious in selecting the right material. Always check compatibility with the fluids involved.

Tips: Keep O rings stored in a cool, dark space. Avoid exposing them to harsh chemicals. Regular inspections can help detect early signs of wear. If you notice any cracking or brittleness, consider replacing them immediately.

| Property | Details |

|---|---|

| Material Composition | Acrylonitrile-butadiene rubber (NBR) |

| Temperature Resistance | -40°F to 250°F (-40°C to 121°C) |

| Chemical Resistance | Good resistance to oils, fuels, and hydraulic fluids |

| Typical Applications | Automotive, aerospace, industrial machinery |

| Advantages | Durability, cost-effectiveness, good sealing capabilities |

| Limitations | Not suitable for ozone or weather exposure, limited high-temperature performance |