Nitrile O Rings are essential components in many industries. These rings offer a reliable sealing solution. They are made from synthetic rubber, known for its durability. Nitrile O Rings are widely used in automotive, aerospace, and manufacturing sectors.

The versatility of Nitrile O Rings makes them a popular choice. They resist oil, fuel, and various chemicals. This resistance helps them perform effectively in challenging environments. However, not all grades of Nitrile O Rings are created equal. Choosing the right type can be a complex decision. Understanding specific requirements is vital for optimal performance.

In some cases, users overlook the importance of proper installation. Incorrect placement can lead to failures and leaks. Regular inspection can mitigate these risks. While Nitrile O Rings are reliable, one should not take them for granted. Mistakes can have costly consequences in industrial applications.

Nitrile O rings are important seals used in various industries. They are made from a synthetic rubber called nitrile rubber. This material is resistant to oil and fuels. That makes them a popular choice for automotive and aerospace applications. The rings are durable and can withstand a range of temperatures. However, they may not be suitable for all environments.

These O rings come in different sizes. Each size fits a specific application. Proper sizing is crucial for effective sealing. If the O ring is too small, it might leak. Conversely, if it’s too big, it might not stay in place. This can lead to issues in machinery and equipment.

In addition to their oil resistance, nitrile O rings are also used in hydraulic systems. They help prevent fluid leaks, ensuring the system functions properly. Despite their advantages, they can degrade over time. Proper maintenance is essential. Regular inspections can help identify wear and tear. This proactive approach can save costs and avoid unscheduled downtimes.

Nitrile rubber, also known as Buna-N, is a popular synthetic material. Its composition primarily includes acrylonitrile and butadiene. This composition gives nitrile rubber excellent resistance to oils and fuels. It also provides good elasticity and tensile strength. The balance of these two components determines the properties of the rubber.

Nitrile O rings made from this rubber are commonly used in various industries. They perform well in harsh environments. For instance, they can withstand high temperatures and aggressive chemicals. Despite their advantages, nitrile rubber has limitations. It is less effective when exposed to ozone or sunlight. This can lead to premature degradation under specific conditions.

Many industries rely on nitrile O rings for sealing applications. Automotive and aerospace sectors frequently use them. However, users must consider the operating environment. Sometimes, a different compound may be necessary. Understanding the specific needs is crucial for ensuring optimal performance. Regular assessments of performance in real-world applications can prevent failures.

Nitrile O rings are critical components in many industrial applications. They serve as seals that prevent leakage and protect equipment from contaminants. In industries like automotive and aerospace, these rings are vital for reliable performance. According to a recent market analysis, nitrile O rings account for approximately 40% of the rubber sealing market due to their durability.

In the oil and gas sector, nitrile O rings are often used in drilling equipment and pipeline applications. Their resistance to hydrocarbons makes them an ideal choice. A report highlighted that improper sealing can lead to significant financial losses. An estimated 10% of drilling failures stem from seal issues, underscoring the necessity for quality O rings.

The food industry also benefits from nitrile O rings. They provide a sanitary seal, crucial for maintaining product safety. Yet, not all nitrile materials meet stringent food safety requirements. Regular audits reveal that 20% of manufacturers do not comply with the necessary standards. This poses risks that should not be overlooked.

Nitrile O rings are a popular choice for sealing applications in various industries. Their rubber material offers excellent resistance to oils and fuels. This makes them ideal for automotive and aerospace uses. They can withstand temperatures ranging from -40°C to +120°C. Many industries value them for their durability.

One advantage of nitrile O rings is their flexibility. This allows them to form tight seals around components, preventing leaks. They are generally more economical than many other sealing options. Their ability to resist wear and tear increases reliability. However, they can degrade when exposed to certain chemicals or extreme temperatures. Regular assessments are essential.

Nitrile O rings also feature a simple installation process. This saves time during production. Yet, improper installation can lead to failures, causing potential downtime. Companies must train staff to ensure proper handling. Overall, nitrile O rings present a balance of performance and practicality.

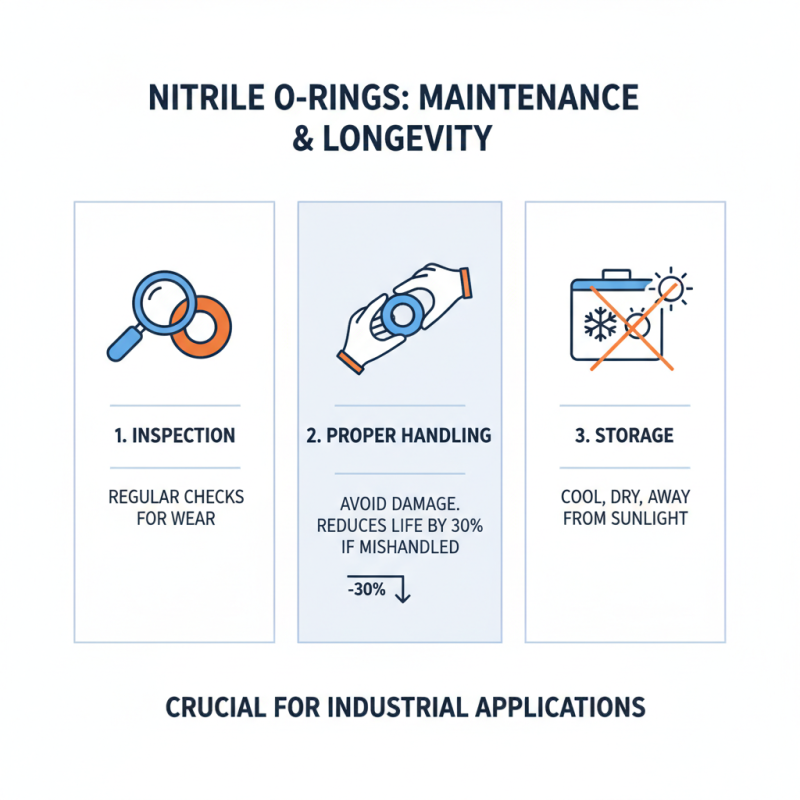

Nitrile O rings are essential components in many industrial applications. Proper maintenance is crucial to ensure their longevity. Regular inspections can help identify wear and tear. Reports indicate that improper handling can lead to a reduction in service life by up to 30%. These rings should be stored in a cool, dry place away from direct sunlight.

Handling nitrile O rings requires care. It's important to avoid sharp objects during installation. Damaging the O ring can cause leaks and failures. Statistics show that 60% of failures in hydraulic systems are linked to improper sealing practices. Operators should also use appropriate lubricants to reduce friction. Using excess lubricant, however, can attract debris, leading to further issues.

Cleaning O rings is also vital. Dirt and contamination can compromise their function. Many experts recommend using a lint-free cloth and mild cleaners. Yet, it's worthy to note that even small residue can hinder performance. Regular training for personnel on best practices can help minimize these risks. Creating a culture of awareness around O ring maintenance is key for operational efficiency.