In the world of sealing solutions, the "Rubber Seal O Ring" plays a crucial role. John Smith, a renowned expert in sealing technology, once stated, "O rings can make or break the integrity of a system." This highlights the importance of understanding their function and application.

Rubber Seal O Rings are circular seals made from various rubber materials. They are simple yet effective in preventing fluid leaks. Their design allows them to fit snugly into grooves, creating a tight seal. This is vital in industries ranging from automotive to aerospace.

Yet, there are challenges. Not all O rings are made equal. Selecting the wrong material can lead to failure. This can cause damage, waste, and safety risks. Understanding the right attributes, such as temperature tolerance and chemical resistance, is essential. Thus, while a Rubber Seal O Ring seems straightforward, its application demands careful consideration and expertise.

Rubber seal O rings are vital components in various industrial applications. Their primary function is to create a tight seal between two surfaces. They help prevent liquids or gases from leaking. O rings are typically made from elastomers, including nitrile or silicone. This composition provides durability and flexibility, which are crucial for effective sealing.

According to industry studies, sealing technology represents approximately 15% of the global gasket and sealing market. A significant portion of this market is driven by the automotive and aerospace sectors. Rubber O rings can withstand a range of temperatures, making them suitable for different environments. Some reports indicate they can operate between -40°C and +200°C.

However, not all rubber O rings perform equally. Their lifespan can be affected by various factors, such as pressure, temperature, and exposure to chemicals. Many users overlook these variables. Regular assessments are necessary to ensure optimal performance. Failure to do so can lead to leaks and costly repairs, highlighting the importance of understanding O ring selection and maintenance.

Rubber seal O-rings come in various types, each tailored for distinct applications. One common type is the Nitrile O-ring. Known for its oil resistance, it excels in automotive and aerospace industries. According to a report by Research and Markets, the global O-ring market is projected to reach $5.2 billion by 2025, reflecting their significance in these sectors.

Another type is the EPDM O-ring. This type is resistant to heat and weathering, making it ideal for plumbing and HVAC systems. A study by MarketsandMarkets indicates that the demand for EPDM in automotive applications is growing at a CAGR of 5.4%. Its durability ensures less frequent replacements, yet it’s essential to evaluate the balance between cost and longevity.

While rubber O-rings are reliable, they are not infallible. Poor installation can lead to leaks. Not all O-rings are suited for every environment—a mismatch can result in premature failure. Identifying the correct material and size is crucial. As the industry evolves, continuous research is needed to optimize performance in various applications. Understanding these factors can help businesses minimize downtime and maintenance costs.

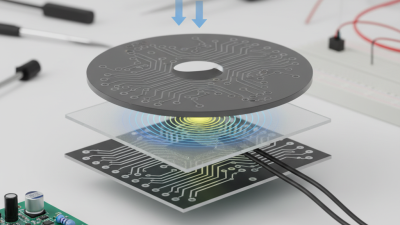

O rings are simple yet effective sealing solutions. They are made from rubber and are shaped like a circle. Their unique shape allows them to fit snugly into grooves. This fit is crucial for creating a reliable seal.

When compressed, the O ring expands and fills the gap between two surfaces. This compression generates enough pressure to block fluids or gases from leaking. The seal holds up under varying temperatures and pressures. However, using the wrong size or material may lead to leaks.

**Tips:** Always check the compatibility of the O ring material with the fluids it will encounter. Regular inspections can identify wear or damage early. If sealing issues arise, reevaluate the installation process.

| Dimension | Value | Material | Application |

|---|---|---|---|

| Inner Diameter | 10 mm | Nitrile Rubber | Automotive Sealing |

| Outer Diameter | 14 mm | Silicone Rubber | Medical Devices |

| Cross Section | 2 mm | EPDM | Industrial Machinery |

| Temperature Range | -40°C to 100°C | Viton | Oil Resistance |

| Pressure Rating | 300 psi | Neoprene | Hydraulic Systems |

In evaluating O-ring performance, several factors come into play. The material composition of the O-ring significantly influences its durability and efficiency. For instance, nitrile rubber, common in many applications, offers good resistance to petroleum products but may fail in hot environments. Research indicates that O-rings can degrade by as much as 50% within just a few months if exposed to harsh chemicals. Proper selection based on the specific application and environment is crucial.

Temperature and pressure conditions also dictate O-ring lifespan. High temperatures can lead to hardening and cracking, while extreme pressure may cause deformation. The Society of Automotive Engineers reports that O-rings operating under excessive pressure can experience up to a 30% reduction in their sealing capabilities. Regular inspections and maintenance are essential to ensuring that O-rings are functioning effectively.

Installation errors often contribute to premature failure as well. Poor alignment can lead to uneven wear and leakage. It’s not uncommon for O-rings to be overlooked during installation, which can result in significant operational issues later. Focusing on proper techniques can help mitigate these risks, extending the life of the O-ring and improving overall performance.

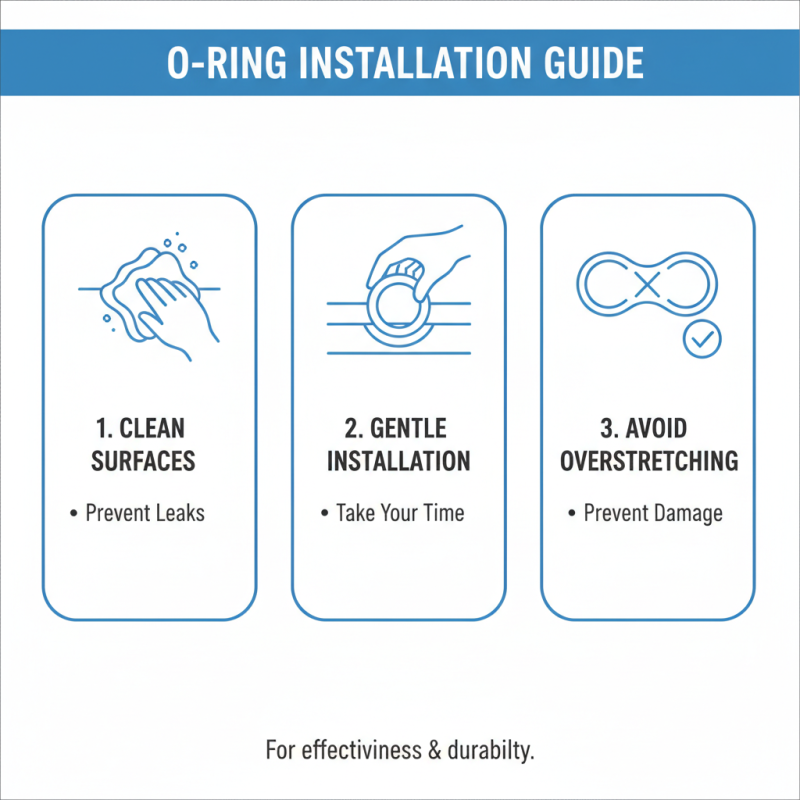

When installing rubber O rings, proper technique is crucial for effectiveness. Clean the surfaces where the O ring will fit. Dust or dirt can lead to leaks. Take your time during installation. Avoid stretching the O ring excessively. This can cause damage.

Consider applying a lubricant suitable for rubber. It aids in installation and reduces wear. Too much lubricant, however, can attract debris. Keep that balance in mind. Regularly check installed O rings for signs of wear or degradation. Visual inspections can prevent unexpected issues.

Maintenance is vital for the longevity of O rings. Store them in a cool, dry place. Exposure to heat or sunlight can cause premature degradation. Replace damaged O rings promptly. Ignoring small issues can lead to larger problems later. A proactive approach will save time and money.