Choosing the right neoprene seal for your projects can be daunting. With many options available, decision-making is often overwhelming. Neoprene seals are essential for various applications, from automotive to plumbing. Their versatility makes them highly sought after.

When selecting a neoprene seal, consider the specific requirements of your project. Factors such as temperature resistance, compression, and durability play a vital role. Not all neoprene seals are created equal. Some may not meet the demands of high-pressure environments, risking leaks or failures.

It’s also crucial to assess the seal's compatibility with the materials in use. Misalignment can lead to significant issues, including decreased performance and increased costs. Understanding these components can be a learning curve. Reflecting on past experiences can help in making better choices for future projects. The path to finding the ideal neoprene seal is filled with trial and error, but it leads to more successful outcomes.

Neoprene is a synthetic rubber with unique properties. It is known for its excellent resilience and flexibility. This makes it a popular choice for seals. According to a report by Global Market Insights, neoprene seals are projected to have a compound annual growth rate (CAGR) of 4.8% over the next five years.

The benefits of neoprene include its resistance to weathering and UV light. That is crucial for outdoor applications. It also has good chemical resistance, making it suitable for various industries. A study from Technavio indicates that nearly 60% of neoprene applications are in automotive and industrial sectors. However, the environmental impact of neoprene production raises concerns. The extraction of raw materials can lead to long-term ecological consequences.

Choosing neoprene for seals requires careful consideration. Despite its advantages, there are issues. Not all neoprene is created equal; variations in quality exist. An improper selection can lead to premature seal failure. It is vital to match the neoprene's properties with the project needs. Consider factors like temperature, exposure conditions, and mechanical requirements. Proper research can mitigate risks associated with choosing the wrong material.

When selecting neoprene seals for your projects, there are several key factors to consider. The environment plays a significant role. Is it exposed to high temperatures or harsh chemicals? Understanding these conditions will guide you in choosing the right type of neoprene seal. Not all neoprene is created equal; some are better suited for specific applications than others.

Another important consideration is size and compatibility. The seal must fit perfectly within the application. An oversized seal may lead to leakage, while one that is too small won’t function properly. Measure twice. Don't rush this step. Additionally, think about the seal's durometer, which indicates its hardness. A softer seal could provide better flexibility but may wear out faster. On the other hand, a harder seal might last longer but could crack under pressure.

Think about long-term performance as well. Will the seal need to withstand frequent movement or remain stationary? This can affect your choice significantly. Pay attention to the installation process too. A seal that’s difficult to install can lead to mistakes and wasted time. Keep these aspects in mind, and reflect on your needs to make better choices.

Neoprene seals are essential components in many projects. Their versatility makes them suitable for a range of applications. There are several types of neoprene seals, each with unique features. For instance, O-rings are commonly used in plumbing. They provide a reliable barrier against leaks. Gaskets, on the other hand, are crucial in machinery. They fill gaps and reduce vibration. This is important for equipment longevity.

Choosing the right type can be tricky. Always evaluate the specific demands of your project. Consider the temperature range. Neoprene can withstand various conditions, but limitations exist. Different thicknesses also affect flexibility and durability. Ensure the seal can handle the environment where it will be used.

Here’s a tip: test a few samples before committing. This can help you see how they perform in real-world conditions. Sometimes, a seal might seem perfect in theory but fails in practice. It’s worth an extra step for reliable results. Remember, details matter when selecting neoprene seals.

| Type of Neoprene Seal | Key Properties | Common Applications | Temperature Range (°C) |

|---|---|---|---|

| Closed Cell Neoprene Seal | Water resistant, good thermal insulation | HVAC systems, marine applications | -40 to 100 |

| Open Cell Neoprene Seal | Flexible, sound absorption | Automotive applications, soundproofing | -30 to 80 |

| Neoprene O-Ring | Effective sealing, oil resistant | Pumps, valves, hydraulic systems | -20 to 120 |

| Neoprene Gasket | Durable, weather resistant | Electrical enclosures, machinery | -30 to 90 |

| Neoprene Foam Seal | Lightweight, compressible | Window sealing, packaging | -40 to 80 |

When choosing neoprene seals for projects, performance and durability are key. Several factors influence how well these seals work over time. Material quality is critical. High-quality neoprene resists wear and environmental factors, extending its lifespan. Look for seals that can withstand extreme temperatures and harsh chemicals.

Another important aspect is the seal's design. The fit and compression properties affect how well the seal protects against leaks or contamination. An improperly designed seal may degrade faster. Always pay attention to specific application needs. Are you sealing a high-pressure system or a simple enclosure? This can drastically change your requirements.

Here are a few tips: always test seals in real-world conditions before full installation. Small variations in thickness can impact your project. Be careful when selecting the size; a too-tight seal can wear excessively, while a loose one can fail. Also, consider the handling process. Mishandling neoprene can lead to premature damage or loss of integrity. Awareness and thoughtful selection will enhance your projects' success.

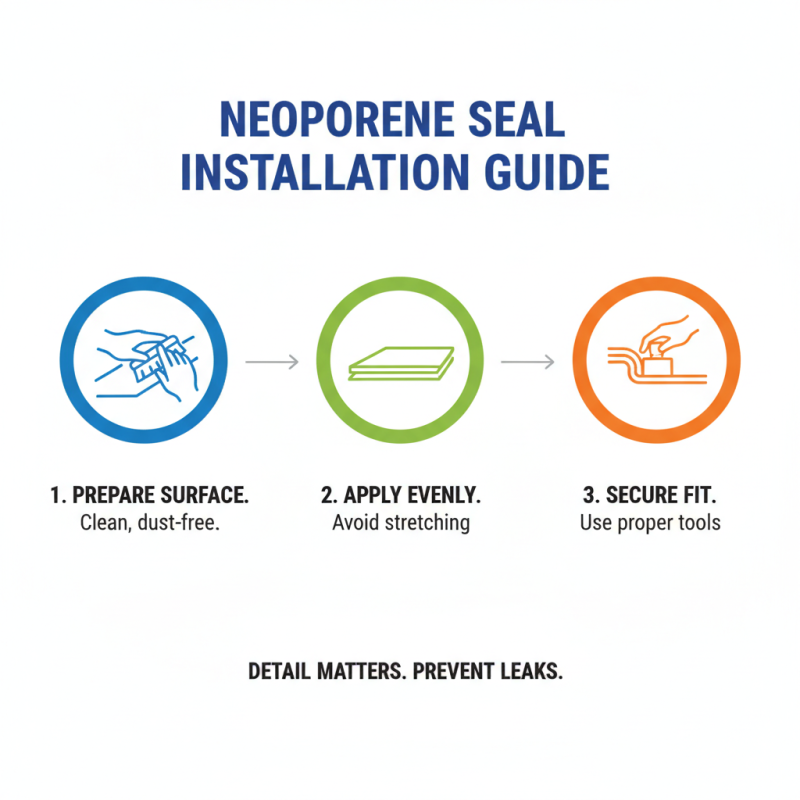

When installing neoprene seals, attention to detail is crucial. Start by ensuring the surface is clean and free from debris. Dust or residue can compromise the seal’s integrity. Apply the seal evenly, avoiding overstretching. An uneven application may lead to leaks. Use appropriate tools for the job to achieve a snug fit without damaging the material.

Maintenance is equally important. Regularly inspect seals for signs of wear or damage. Cracks or hardening can drastically reduce effectiveness. Don’t overlook small issues; they often lead to larger problems later. Cleaning seals with mild soap and water can prolong their lifespan. Be mindful of the environment; extreme temperatures or chemicals can affect neoprene quality.

Sometimes, it’s tempting to skip these steps due to tight deadlines. However, taking shortcuts in installation or maintenance can result in costly repairs. Reflect on the long-term benefits of doing it right. Investing time now can save effort in the future, ensuring that projects run smoothly and effectively.