Nitrile O Rings are essential components in various industries. Their versatility makes them crucial for a range of applications. According to a report by Freedonia Group, the global demand for O rings is projected to grow by 4% annually, driven by increased manufacturing activities.

Experts like Dr. Emily Schwartz, a materials scientist, emphasize, "Nitrile O Rings are vital for sealing solutions." These products are widely used in automotive, aerospace, and medical industries. Their ability to withstand oils and fuels enhances their popularity in these sectors.

Despite their advantages, challenges persist. Not all Nitrile O Rings are created equal. Factors like temperature resistance and chemical compatibility must be carefully evaluated. Choosing the right O ring can lead to failures, affecting equipment performance. Understanding these challenges is key to maximizing their potential in real-world applications.

Nitrile O-rings play a crucial role in the automotive industry. They are essential for sealing applications in engines, transmissions, and fuel systems. Studies show that the automotive sector accounts for over 30% of the global O-ring demand. Their resistance to fuel and oil makes them ideal for these applications. However, not all nitrile compounds are equal. Some may degrade faster under extreme conditions.

In engines, O-rings prevent leaks that could lead to performance issues. For example, a small fuel leak can significantly reduce engine efficiency. Nitrile O-rings withstand high temperatures and pressures, but they may not last forever. Regular monitoring is necessary to avoid unexpected failures. A report from an industry expert notes that about 15% of automotive failures can be traced back to inadequate sealing solutions.

In hydraulic systems, nitrile O-rings ensure proper fluid dynamics. They maintain pressure and reduce wear. However, improper installation can compromise their functionality. A significant number of maintenance issues arise from user error. It's essential to train technicians in proper O-ring handling. The industry's focus on durability highlights the need for ongoing evaluation of sealing materials. There is always room for improvement.

Nitrile O rings play a crucial role in aerospace engineering. These seals provide excellent resistance to fuel, oil, and extreme temperatures. Their usage ensures the reliability of critical aircraft systems. According to the Aerospace Industries Association, around 65% of aircraft systems utilize elastomeric seals like Nitrile O rings. This percentage underscores their importance in this sector.

In fuel systems, Nitrile O rings prevent leaks that could lead to catastrophic failures. Their ability to withstand harsh conditions is essential for engine performance. Many engineers rely on data from organizations like the National Aeronautics and Space Administration (NASA). NASA’s studies indicate that material failure can lead to serious safety issues. Nitrile O rings help mitigate these risks, especially in pressurized environments.

Yet, challenges remain. Material degradation can occur over time. High temperatures can compromise the integrity of Nitrile O rings. Monitoring solutions should be in place to ensure performance. Regular inspections are vital to prevent malfunction. Developing better materials may address these vulnerabilities. The aerospace industry must keep innovating to maintain safety and efficiency.

| Application | Industry | Temperature Range (°C) | Pressure Resistance (psi) | Chemical Compatibility |

|---|---|---|---|---|

| Seals for Hydraulic Systems | Aerospace | -40 to 120 | 3000 | Hydraulic Fluids |

| Fuel System Seals | Aerospace | -40 to 100 | 4000 | Aviation Fuels |

| Oxygen Seals | Aerospace | -60 to 80 | 2500 | Oxygen-rich Environments |

| Engine Components Seals | Aerospace | -40 to 150 | 3500 | Various Fuels and Oils |

| Landing Gear Seals | Aerospace | -50 to 120 | 5000 | Greases and Oils |

| Environmental Seals | Aerospace | -40 to 90 | 3000 | Water and Chemicals |

| Cabin Pressure Seals | Aerospace | -40 to 70 | 4000 | Air and Gases |

| Control Surface Seals | Aerospace | -50 to 100 | 3000 | Hydraulic Fluids |

| Suction Seals | Aerospace | -30 to 90 | 3500 | Gases and some Chemicals |

| Pneumatic Seals | Aerospace | -40 to 150 | 2500 | Compressed Air |

Nitrile O Rings play a crucial role in the oil and gas industry. These rings are designed to seal connections, preventing leaks in high-pressure environments. Nitrile, known for its excellent resistance to oil and gas, is an ideal choice. The versatility of nitrile O Rings makes them suitable for various applications, from exploration to refining.

In drilling operations, Nitrile O Rings protect valves and pumps under extreme pressure and high temperatures. They withstand harsh chemicals found in drilling fluids. According to industry reports, about 30% of equipment failures in this sector are due to seal-related issues. Proper use of nitrile O Rings can significantly reduce these failures.

In pipeline transport, these O Rings seal joints and connections. This prevents costly leaks and maintains product integrity. A major study indicates that leaks in pipelines can cost the industry billions each year. Utilizing reliable sealing solutions like nitrile O Rings is essential. However, ensuring the right size and type is critical; improper selection can lead to dangerous failures. The importance of these components cannot be overstated.

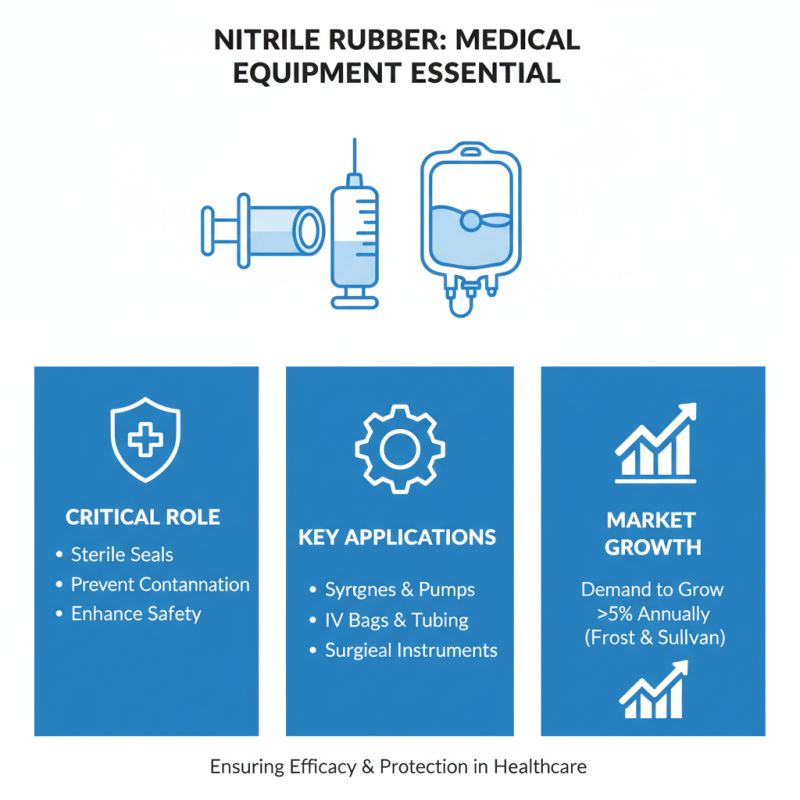

Nitrile O rings play a critical role in medical equipment manufacturing. These seals are essential in devices like syringes, IV bags, and surgical instruments. They help maintain sterile conditions, preventing contamination. According to a market analysis by Frost & Sullivan, the demand for nitrile rubber in the medical sector is projected to grow by over 5% annually. This growth highlights their importance in ensuring safety and efficacy in medical applications.

The durability of nitrile O rings makes them ideal for high-pressure environments found in medical devices. They can withstand a wide range of temperatures and chemicals, which is crucial for sterilization processes. However, there are challenges with maintaining their integrity over time. Aging can lead to degradation, influencing performance. A study from the Journal of Biomedical Materials Research noted that improper storage could also impact their effectiveness.

While nitrile O rings offer numerous benefits, not all medical applications are suitable for them. In certain scenarios, alternative materials may outperform nitrile. Understanding these limitations is vital. Continuous research is needed to enhance the material properties of O rings for medical use. Investing in better testing methods could improve their reliability in critical applications.

Nitrile O rings are widely used in household appliances and electronics. They offer excellent resistance to oils, heat, and chemicals. These features make them ideal for seals in many devices we use daily.

In kitchen appliances, nitrile O rings play a crucial role. They help create airtight seals in mixers and blenders. This ensures that food is processed efficiently without leaks. In refrigerators, O rings ensure doors close tightly. This keeps food fresh and reduces energy waste. However, sometimes these seals degrade over time, which can lead to inefficient operation.

In electronics, nitrile O rings are vital for protecting sensitive components. They provide sealing in devices like printers and heating elements. Here, moisture and dust can cause performance issues. But not all applications consider longevity. Some users may overlook regular checks, which could lead to device failures. Using nitrile O rings in these contexts helps maintain device efficiency, but they require attention for optimal performance.