The advancement of electronics technology has opened up new horizons in various applications, one of which has become increasingly prominent: Ito Thin Films. These films, composed of Indium Tin Oxide (ITO), are renowned for their unique electrical and optical properties, making them indispensable in modern electronic devices. As Dr. Emily Chen, a leading expert in thin film technology, points out, "Ito Thin Films are not just materials; they are the backbone that supports the innovative capabilities of contemporary electronics."

In recent years, the demand for ITO in the development of touchscreens, solar cells, and flat-panel displays has surged, attributed to their excellent conductivity and transparency. Understanding the applications and benefits of Ito Thin Films is crucial for engineers and developers aiming to harness their potential in energy-efficient and high-performance devices.

This exploration into the realm of Ito Thin Films will unveil their pivotal role in enhancing device functionality, optimizing energy consumption, and pushing the boundaries of electronic design. By delving deeper into the science and applications of Ito Thin Films, stakeholders can better appreciate how these materials are shaping the future of technology.

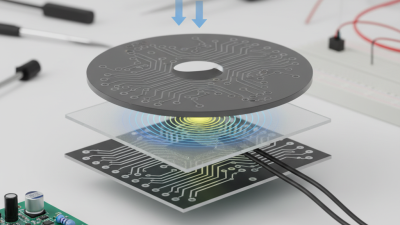

Indium Tin Oxide (ITO) (ITO) thin film technology has emerged as a pivotal component in the realm of electronics, primarily due to its unique combination of electrical conductivity and optical transparency. This technology involves the deposition of a thin layer of indium tin oxide onto various substrates, creating a versatile material widely used in devices such as touchscreens, solar cells, and flat panel displays. The primary advantage of ITO films lies in their ability to conduct electricity while allowing visible light to pass through, making them ideal for applications where both electrical and optical performance is critical.

Moreover, the fabrication of ITO thin films has continually evolved, incorporating methods such as sputtering, chemical vapor deposition, and pulsed laser deposition. These techniques not only ensure uniformity and quality of the films but also allow for customization of electrical and optical properties by varying the composition and thickness. As a result, researchers and engineers can optimize ITO thin films for specific applications, enhancing device performance and efficiency. The integration of ITO technology into the electronics sector signifies a significant leap toward more effective and innovative solutions, benefiting fields ranging from consumer electronics to renewable energy systems.

Indium Tin Oxide (ITO) is a critical material in the realm of electronics, chiefly known for its unique combination of electrical conductivity and optical transparency. This distinctive property allows ITO to function effectively as a transparent conductor, making it indispensable in modern electronic devices. The high optical transmittance across a broad range of wavelengths enables its use in applications such as touchscreens, LCDs, and solar cells, where visibility and interaction are paramount. Additionally, ITO’s conductivity is augmented by the presence of tin, which contributes to its stable electrical performance, a crucial feature for devices that rely on steady current flow.

Another key property of ITO is its surface characteristics that can be modified to enhance adhesion and compatibility with various substrates. This attribute is particularly beneficial in multilayer electronic structures, where interfaces between different materials can significantly influence overall performance. The ability to tailor surface properties not only improves the effectiveness of coatings but also facilitates the integration of ITO into more complex systems. Moreover, ITO is stable under a range of environmental conditions, providing resilience in various applications, which is essential for the longevity and reliability of electronic components. These intrinsic qualities highlight ITO's significance in pushing the boundaries of electronic innovations.

Indium tin oxide (ITO) thin films have emerged as crucial components in various electronic devices due to their unique properties. One of the most common applications of ITO thin films is in display technology. ITO serves as a transparent conductive oxide (TCO) in liquid crystal displays (LCDs) and organic light-emitting diodes (OLEDs). This material allows for the passage of light while conducting electricity, making it ideal for screens where visibility and functionality are paramount. The ability to create touch-sensitive screens has also been enhanced by ITO, facilitating the proliferation of smartphones and tablets.

Another significant application of ITO thin films is in photovoltaic cells. In solar panels, ITO acts as an electrode that collects and transmits electrical charges generated from sunlight. Its high transparency and conductivity improve the overall efficiency of solar energy conversion, which is essential for enhancing the performance of renewable energy systems. Furthermore, ITO thin films are utilized in sensors and smart windows, where they play a role in energy-efficient building designs by regulating heat and light transmission. This diverse utility underscores the importance of ITO thin films in advancing modern electronics and promoting sustainable technologies.

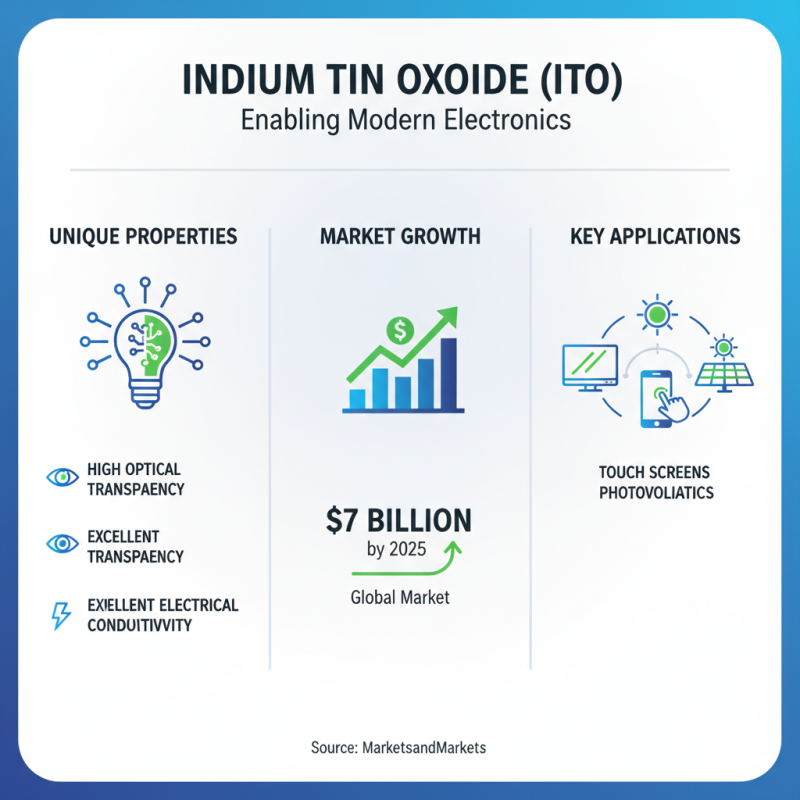

Indium Tin Oxide (ITO) is an essential component in modern electronics, offering unique properties that are pivotal for the development of advanced electronic devices. One of the primary benefits of using ITO is its high optical transparency combined with excellent electrical conductivity. According to a market research report from MarketsandMarkets, the global ITO market is expected to reach $7 billion by 2025, driven by its increasing applications in displays, touch screens, and photovoltaics. This remarkable dual functionality makes ITO a preferred choice for manufacturers looking to enhance the performance of their products without compromising on aesthetic design.

Moreover, ITO plays a crucial role in the development of next-generation devices such as flexible displays and sensors. Its ability to be deposited as a thin film allows for the creation of lightweight and bendable electronic components that can be integrated into a variety of surfaces. A report from Grand View Research highlights that the demand for flexible electronics is projected to grow at a CAGR of 16% from 2021 to 2028, further underscoring the significance of materials like ITO in enabling innovations in the industry. Furthermore, ITO's stability under various environmental conditions ensures the longevity and reliability of electronic devices, making it indispensable in sectors that require durability, such as automotive and aerospace industries.

The development of Indium Tin Oxide (ITO) thin films has been at the forefront of electronic advancements, especially in touch screens and transparent conductive layers. However, several challenges remain in optimizing their properties for next-generation applications. One significant hurdle is the need for improved conductivity without sacrificing transparency. ITO’s inherent brittleness also poses challenges for flexible electronics, where durability is paramount. The growing demand for sustainable materials also urges researchers to find alternatives that can compete with ITO in terms of performance and manufacturability.

Tips: When exploring the potential of ITO thin films, consider the integration of advanced fabrication techniques, such as atomic layer deposition, which may enhance film uniformity. Additionally, researchers are focusing on doping methods to improve conductivity while maintaining transparency, paving the way for future innovations.

As we look toward the future, the search for environmentally friendly alternatives to ITO is gaining momentum. Materials such as graphene and conductive polymers are being studied for their potential replacements, promising to overcome ITO's limitations while being less harmful to the environment. Collaborations across disciplines are becoming critical, as interdisciplinary approaches may lead to breakthroughs in enhancing thin film technology in electronics.

| Application | Benefits | Challenges | Future Trends |

|---|---|---|---|

| Touch Screens | High transparency, excellent conductivity | Fragility, cost of raw materials | Integration with flexible substrates |

| Solar Cells | Increased efficiency, lightweight | Stability under varying weather conditions | Transparent conductors for better light absorption |

| LEDs | Improved light output, conductivity | Manufacturing complexity | Development of new composite materials |

| Displays | High clarity, effective heat dissipation | Environmental degradation | Sustainability practices in production |